Measuring Squareness on Machinery

Many machine tools rely on the squareness or perpendicularity between moving tables, slides, or tools in order to produce parts that are square. If machinery isn’t squared properly, it will […] Read more ›

Many machine tools rely on the squareness or perpendicularity between moving tables, slides, or tools in order to produce parts that are square. If machinery isn’t squared properly, it will […] Read more ›

The terms “level” and “flat” are used interchangeably and, in some cases, assumed to mean the same thing. In fact, they are different, but both can be measured using laser […] Read more ›

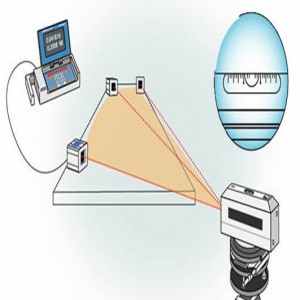

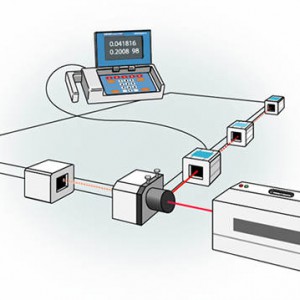

When using a laser alignment system to check a machine or sub-assembly for straightness, flatness, bore alignment and many other geometric parameters, we often need to normalize the laser reference […] Read more ›

Many machine tools rely on the squareness or perpendicularity between moving tables or slides and also the axis of travel for a cutting bit. Traditional methods for checking the squareness […] Read more ›