Stop the Presses!

In this article, you will learn about: What happens when rolls are not properly aligned Preventative Maintenance is quick and precise Decrease downtime, increase productivity When an editor yells, […] Read more ›

In this article, you will learn about: What happens when rolls are not properly aligned Preventative Maintenance is quick and precise Decrease downtime, increase productivity When an editor yells, […] Read more ›

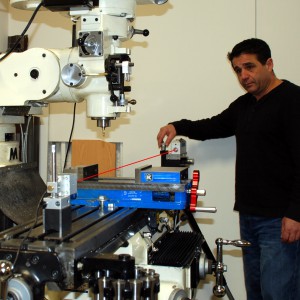

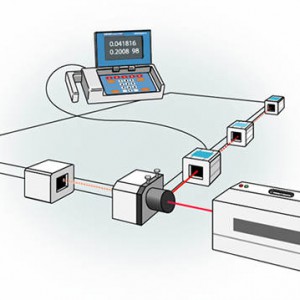

Application: Straightness and linear measurement solutions for CNC equipment Aligning most CNC machinery can be critical for proper performance. If your goals in aligning CNC mills, lathes and gantries is to […] Read more ›

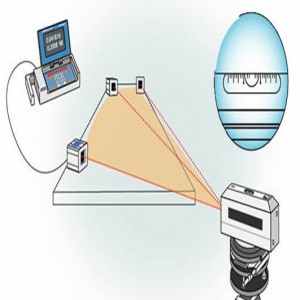

In order for a machine to work properly and produce high quality parts, it must be straight. Straightness can be measured using laser alignment equipment, which has a multitude of […] Read more ›

The terms “level” and “flat” are used interchangeably and, in some cases, assumed to mean the same thing. In fact, they are different, but both can be measured using laser […] Read more ›

Lathes, milling machines, jig borers, grinding machines, and other machine tools all have moving slides or tables that experience wear. Power failures, programming errors, and failing parts can result in […] Read more ›

Recently, Pinpoint Laser Systems developed two new Laser Microgage mounts that can accommodate bore diameters as large as 3 feet and as small as 2 ½ inches for a large […] Read more ›

When using a laser alignment system to check a machine or sub-assembly for straightness, flatness, bore alignment and many other geometric parameters, we often need to normalize the laser reference […] Read more ›

Many machine tools rely on the squareness or perpendicularity between moving tables or slides and also the axis of travel for a cutting bit. Traditional methods for checking the squareness […] Read more ›