When production in your factory or manufacturing plant stops because a machine or equipment is out of alignment, it’s like pouring money down the drain. While calculating the exact costs of downtime can be difficult to determine, it is something that every manufacturing plants need to know how to do. No matter the industry, factories and manufacturers often lose between 5% and 20% of its productivity.

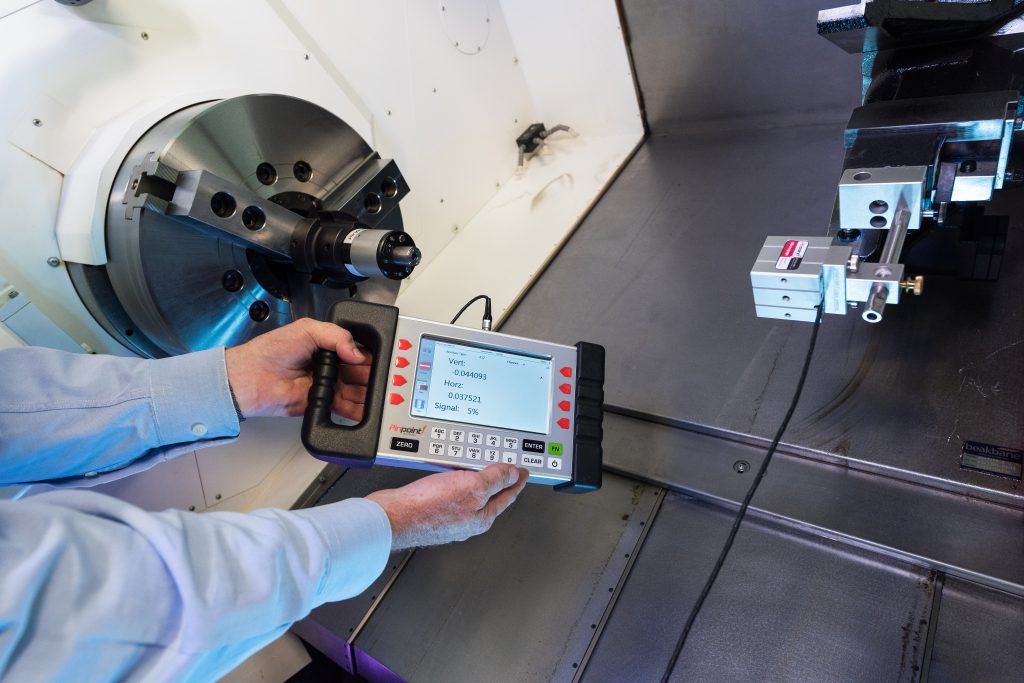

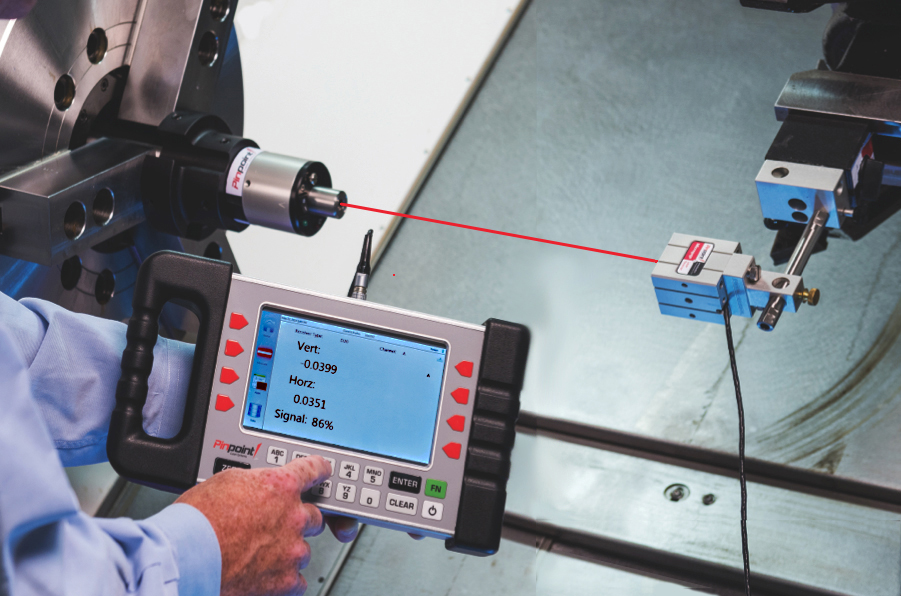

Proactively identifying misalignment with a Pinpoint laser alignment system and correcting the issue on the spot reduces machine wear, costly breakdowns and lost production time all the while downtime and lost revenue is minimized.

What goes into factoring the cost of downtime?

Short answer – a lot.

Long answer – labor downtime, overtime costs, the length downtime, scrap costs, the cost of hiring an outside service among other factors.

Performing alignment tasks in-house saves your team invaluable time and money.

To calculate downtime you need to take into account many factors including, the hourly salary rate of machine or equipment operators, time needed for an outside alignment company to get to your facilities, costs for performing the actual alignment service, the cost of lost products while your machine is down, the amount of lost materials, overhead costs and the costs for delayed customer delivery.

Apart from the production output that needs to be redone, there is also the opportunistic cost of additional production that must be delayed. This means there is a good chance the downtime will cost thousands of dollars! Not the ideal situation for any manufacturer.

While downtime is a reality in the manufacturing industry despite even the most proactive of machine operators, it adds up quickly and affects your bottom line – profitability. With that being said, you have the ability to play an integral part in how often downtime could (potentially) happen and to minimize these costs by implementing a preventative maintenance process.

When machine alignment is handled in-house using a laser alignment system, employees are able to check their machines for misalignment more frequently and develop a forward-thinking vision for preventative maintenance. Machine operators and employees are far more likely to know what the machine is doing at all times and therefore know when the equipment needs to be aligned for better operation and better quality product. Furthermore, manufacturing personnel can optimize systems on a regular basis or whenever the need arises.

For manufacturers who choose to handle alignment and measurement issues in-house, machine operators and maintenance staff are able to perform preventative maintenance measures on a consistent basis to better accommodate their scheduling needs. Because the alignment equipment, like Pinpoint’s Microgage PRO, is available in-house, you do not need to spend money to hire an outside contractor – wait for them to arrive, to set up their alignment equipment and then to perform the alignment. When misalignment does occur, staff engineers or machine operators can quickly determine the problem and the realignment process can begin to get your equipment up and running again to support both your production needs and profit expectations.

If you’re interested in bringing alignment and measurement services in-house, use our ROI Calculator to help calculate the costs of downtime and learn how quickly a Pinpoint laser alignment system can pay off for your manufacturing team.