Spindle Data Routine

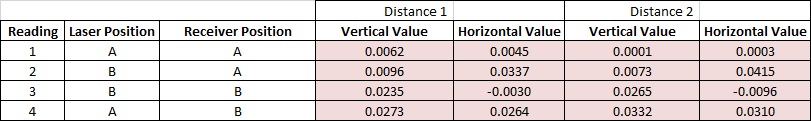

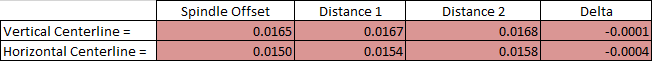

Data analysis and calculations for aligning spindles

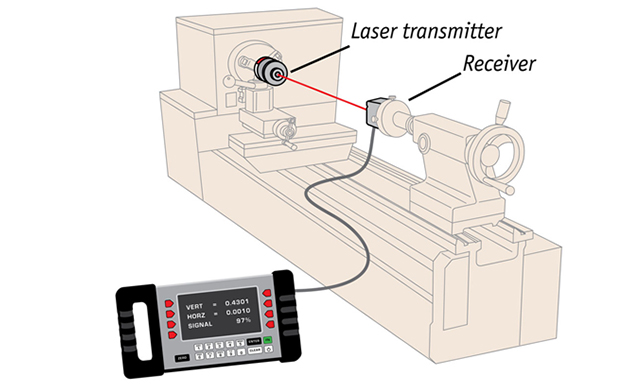

How to Align Spindles With the Cylindrical Laser

Step by Step Instructions

- Set up laser transmitter and receiver at Distance A. (Nearest point on object to be measured).

- Check receiver at Distance B. (Furthest point on object to be measured).

- Un-zero receiver values if activated.

- Clear all data from the Microgage data registers on Capture™.

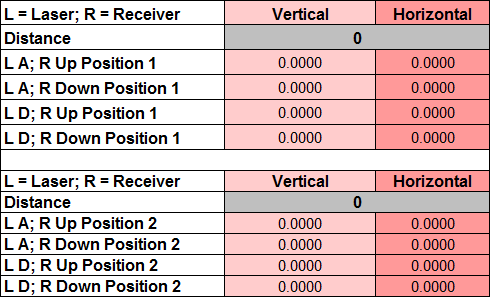

- Move the receiver to the first measurement position (Distance A).

- Input distance from the front of the laser to the front of the receiver in Annotation Field.

- Make sure that A is up on laser, and label is up on receiver and hit Record Data on spreadsheet.

- Rotate laser so that D is up and hit Record Data on spreadsheet.

- Rotate receiver so that Label is down and hit Record Data on spreadsheet.

- Rotate laser so that A is up and hit Record Data on spreadsheet.

- Move the receiver to the second measurement position (Distance B).

- Repeat steps 6-10 at Distance B.

Typical Spindle Alignment Applications

- Align lathes and turning centers

- Position and adjust opposing spindles

- Align boring equipment

- Monitor and adjust machine tools

- Align bearings and shaft supports

- Align bar feeder

- Plus many other applications