Machinery Leveling

A laser beam extends over great distances. A built-in 10-arc-second precision level brings the beam into a level, horizontal orientation.

How it works

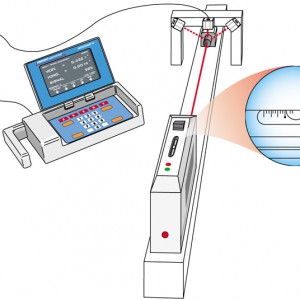

For machinery leveling, the Microgage Laser is placed onto the 4-Axis Precision Mount and adjusted until the precision bubble is centered. The laser is now level and measurements can be made off it using the Microgage receiver.

Level planes are created using the Leveler Rotational Mount. The laser is rotated between the 12:00 and the 6:00 position and the bubble adjusted to center. This process is repeated for the 3:00 and 9:00 positions to insure than the plane of laser light is level. Now the Microgage receiver is moved to a position and the laser swung to meet it for each measurement.

Typical machinery leveling applications

- Leveling long test systems and tanks

- General machinery leveling and placement

- Aligning fourdriniers on paper making machinery

- Leveling slides and mechanical stages

- Adjusting precision conveyors & transport units

- Checking crowned rollers and idlers

Products Needed

- Microgage PRO Plus or Microgage 2D or Microgage 2000

- Moveable leveler rotational mount for setting level planes

- 4-Axis, adjustable precision mount for precision level lines

Useful Accessories

- Precision Tripod Mount

- Computer Interface & Pinpoint Capture for recording and mapping readings

- Roll Mount for checking rolls and web systems

- Adjustable Receiver Base

Find your solution here

Not sure which laser alignment product is right for your job? Get expert advice from our engineers, contact us today.