Parallelism Measurement

Establish parallel reference lines accurate to within 0.001 inch over considerable distances. Ideal for checking machinery, web and roll systems, and production equipment.

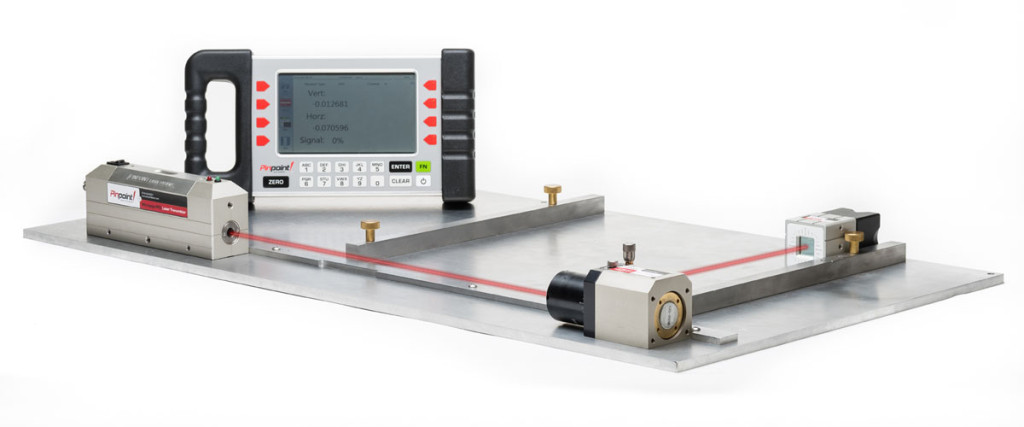

How it works

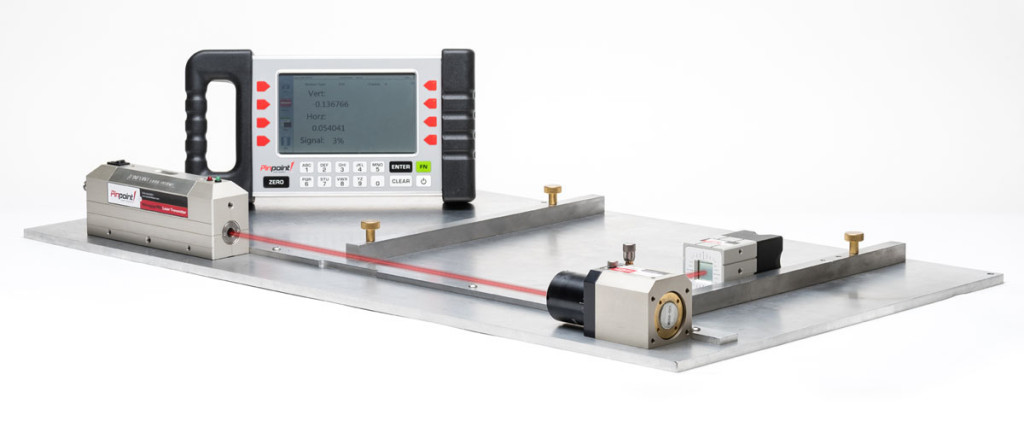

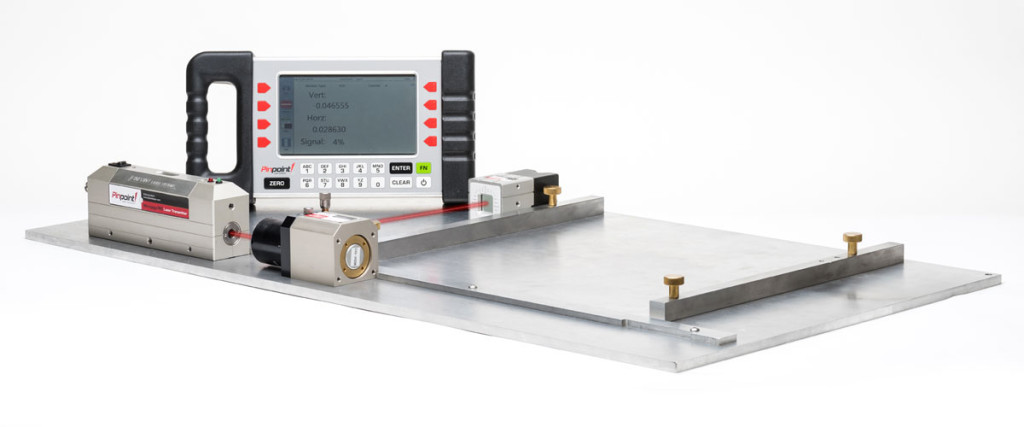

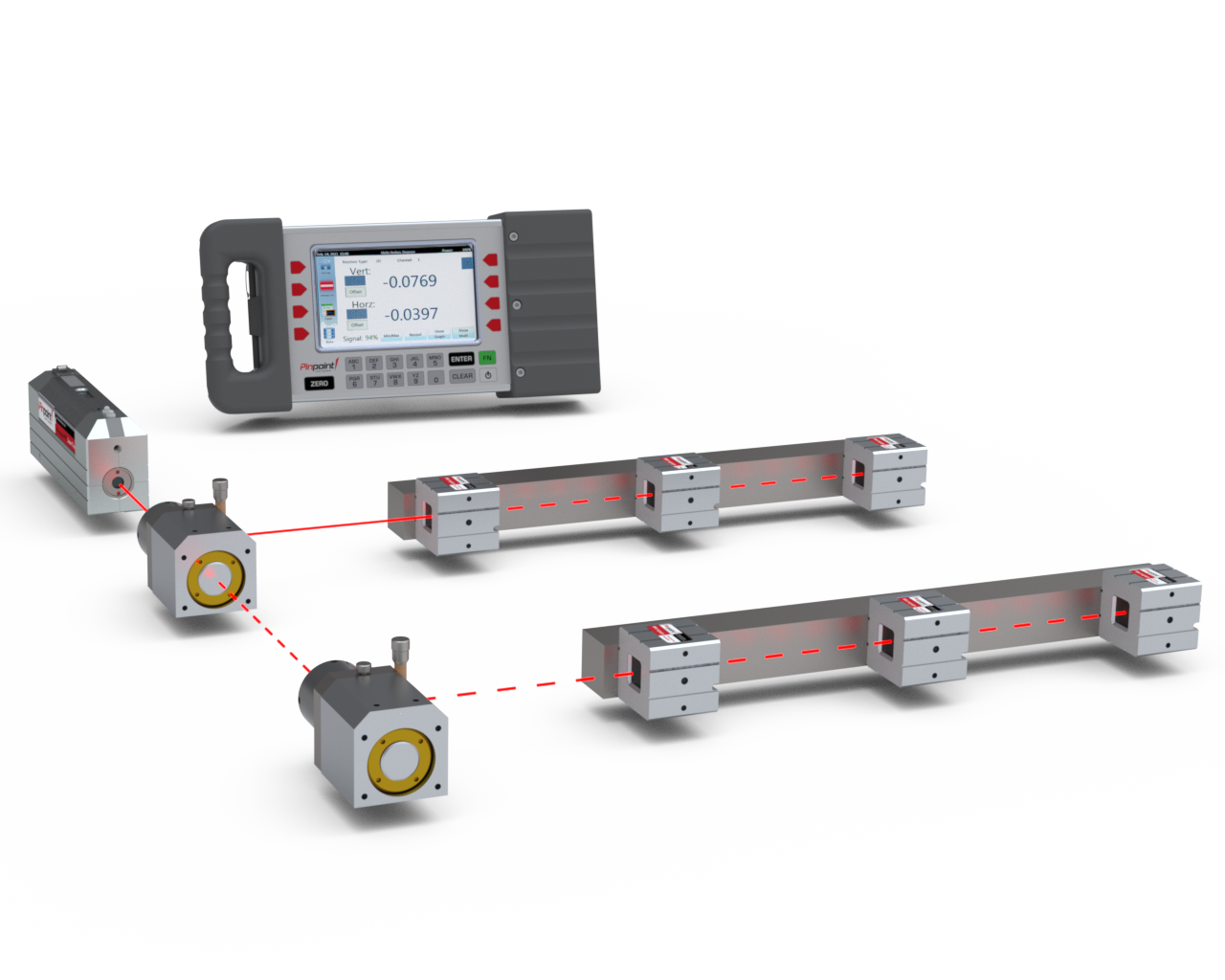

For parallelism measurements, the 90-Line is moved sequentially along the laser path to create multiple reference lines, or planes, that are each square to the original laser reference line and parallel to each other. Along each of these individual square reference lines, the Microgage receiver takes a series of readings to see how that surface, shaft, track, or object is positioned relative to the square laser reference beam. The 90-Line is then moved to a new position, creating another square laser line, parallel to the last line, which measures the position of the next track, shaft, or surface.

Comparing your readings for each surface tells you precisely if the surfaces are out of parallel, by how much, and in which direction. By turning the nosepiece of the 90-Line or the 90-Line Square Plane, the laser can be directed upwards or downwards so that parallelism can be checked for items that do not lie in the same plane.

Typical parallel measurement applications

- Measuring and aligning rollers and web handling systems

- Aligning precision tracks and guide rails

- Installing gantry slides and router assemblies

- Checking and aligning pallet loaders

- Align unwind and take up roll sections

- Measuring parallel edges

- Aligning sprocket and drive systems

- Checking columns on injection molding machines

- And many other applications

Components Needed

Useful Accessories

- 90-Line Right Angle

- 4-Axis Precision Mount

- Precision Tripod Mount

- DCU 2D interface for use with a laptop or PC

- 2D Transparent Receiver

What our customers say

My guys love it. Once you get thru the fixture process the alignment process is by far easier, quicker and more accurate.

David Corbin — Metal Trades

Find your solution here

Not sure which laser alignment product is right for your job? Get expert advice from our engineers, contact us today.