Precision Angular Alignment

Very precise angular alignment measurements and adjustments in the range of 1 degree to 0.00002 degree, simply and precisely.

How it works

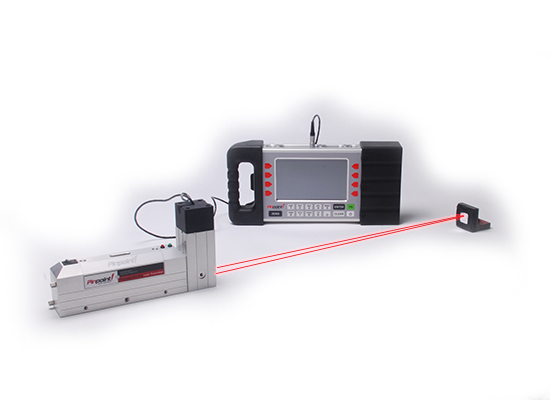

The laser transmitter projects a reference beam to a precision mirror that is resting on the surface to be measured. The laser beam is reflected off the mirror and back to the laser transmitter and an internal Microgage receiver that can precisely measure the X/Y position of the return beam. If the mirror is tilted in the vertical or horizontal direction, the reflected laser reference beam will move accordingly and is recorded by the internal receiver and displayed on the Microgage system. Given the length of the laser beam travel, and the precision of the internal Microgage receiver, angular measurements as small as 0.00002° or 0.1 arc seconds can be measured in real time.

This system, with its high angular precision and accuracy, is well-suited for measuring angular rotation of antenna systems, profiles of surface plates and precision machine tool beds, alignment of rolls and idlers, and many other precision machine applications. Coupling with Pinpoint’s popular Capture program, readings can be calculated, plotted, and stored for analysis.

With the 2 Axis Microgage Receiver and the mirror sensor used in combination, angular deviations of the mirror sensor assembly change the angle of the returning beam. As the laser path length increases, the deviation on the receiver becomes larger for a given angular motion on the plate. Working with a defined number of preset calibration positions allows for calculations to be made for particular laser path and angle calculations. This has been easily achieved using the Pinpoint Capture Spreadsheet or running an onboard application with the new Microgage PRO system.

Typical angular alignment applications

- Adjusting x-ray and medical equipment

- Aligning precision antenna arrays

- Checking the flatness of surface plates

- Monitoring angular runout on machine tools

- Checking flange orientation to bores

- Gearbox and drive system alignment

- Periscope and telescope alignment

Products Needed

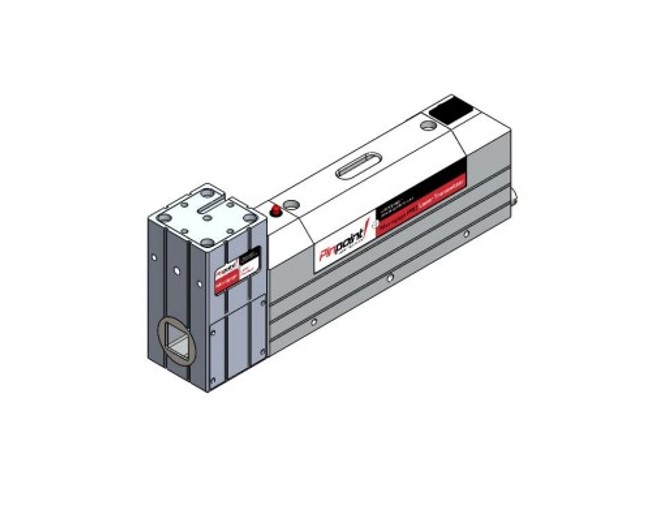

- Microgage PRO Plus

- Microgage 2D

- Microgage 2000

- Angle Measuring Prism

- Laser and Receiver Mounting Plate

Useful Accessories

- DCU-200 Computer Interface & Software

- 4-Axis Precision Mount

- Precision Tripod Mount

Find your solution here

Not sure which laser alignment product is right for your job? Get expert advice from our engineers, contact us today.