Custom Alignment Equipment

Pinpoint has worked with many customers developing special solutions to their particular applications and product needs.

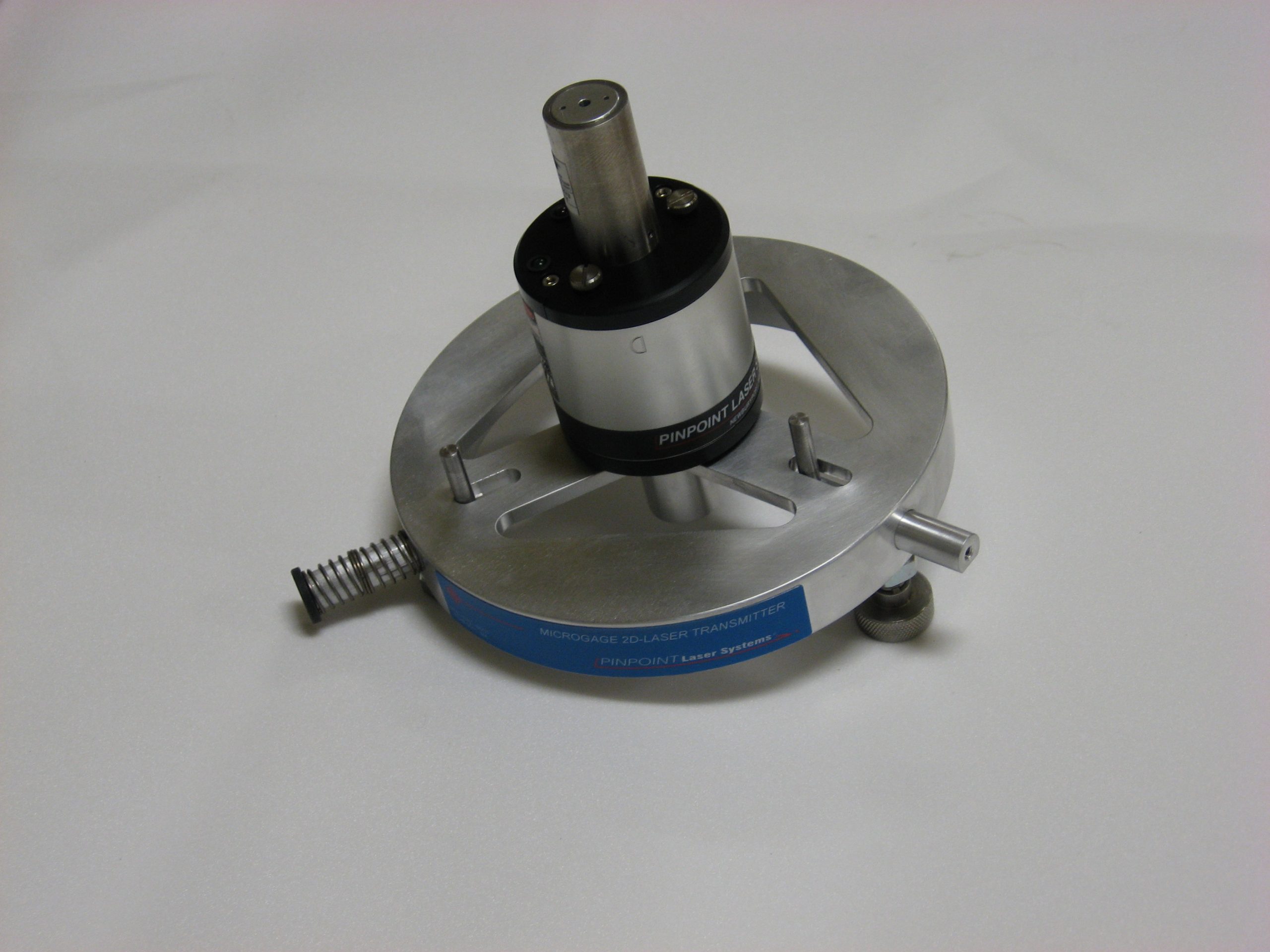

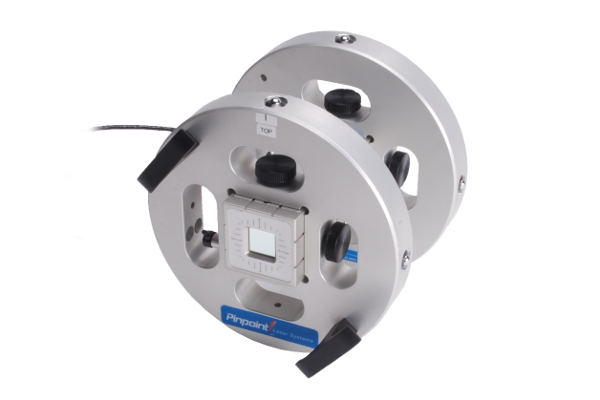

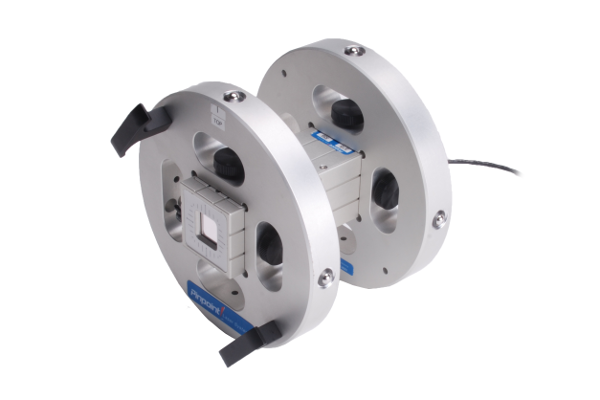

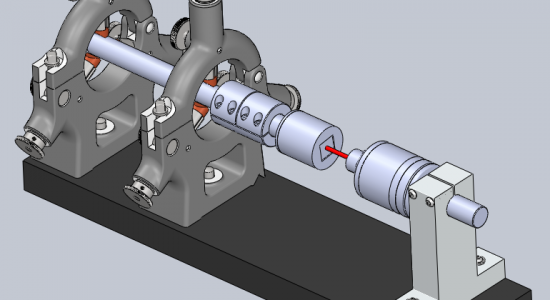

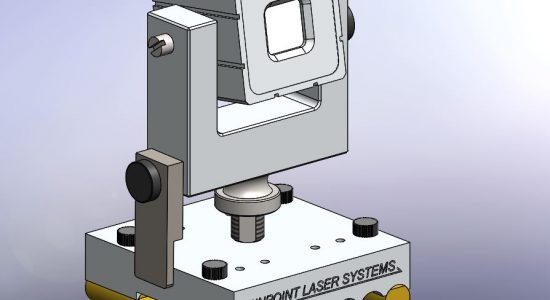

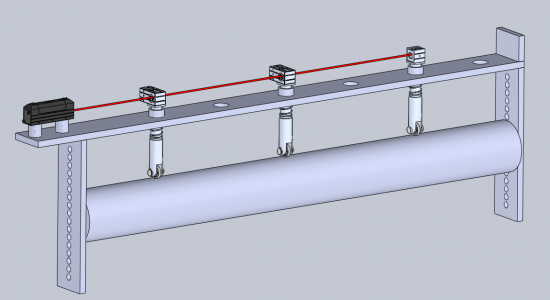

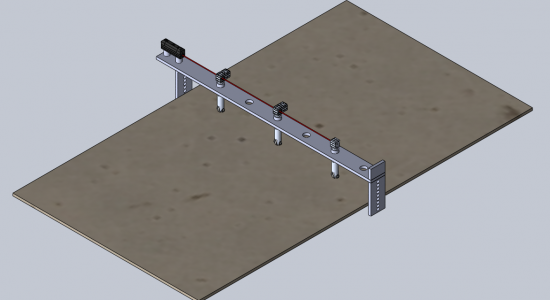

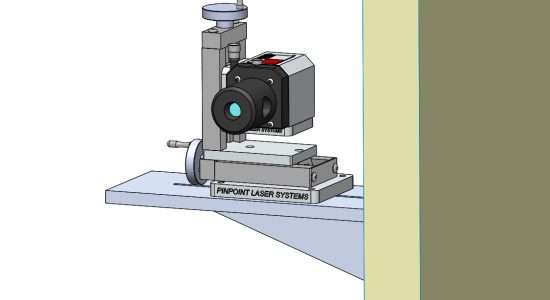

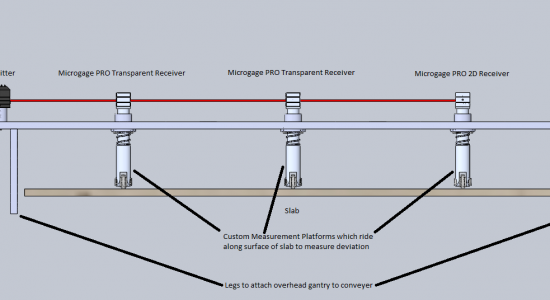

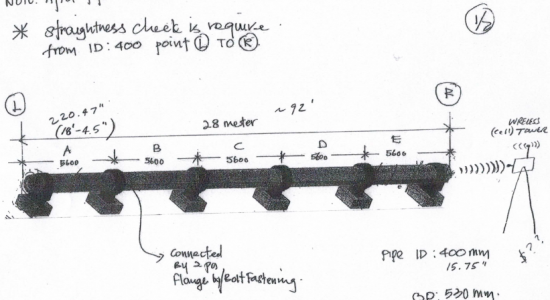

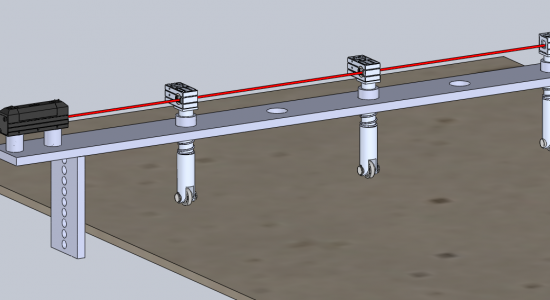

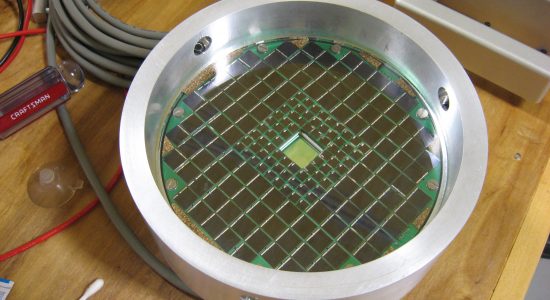

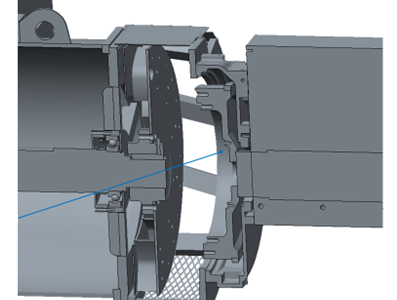

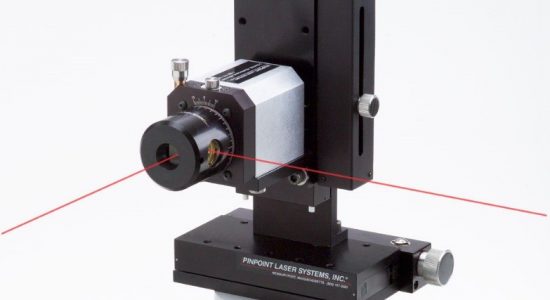

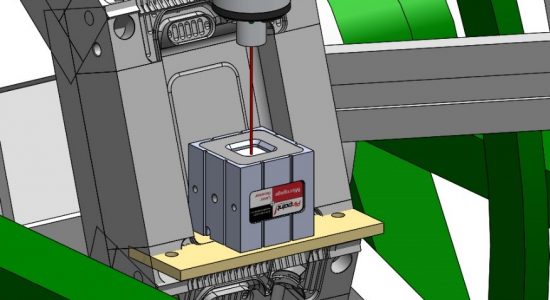

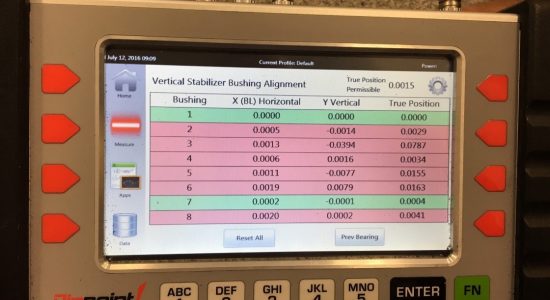

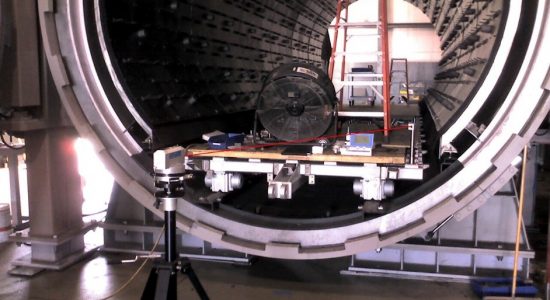

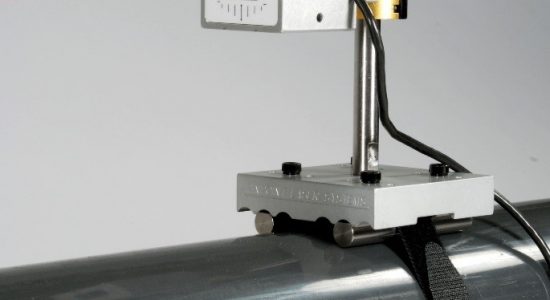

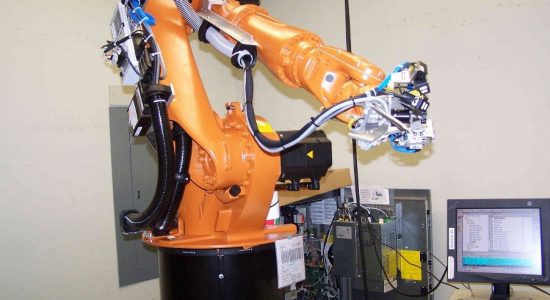

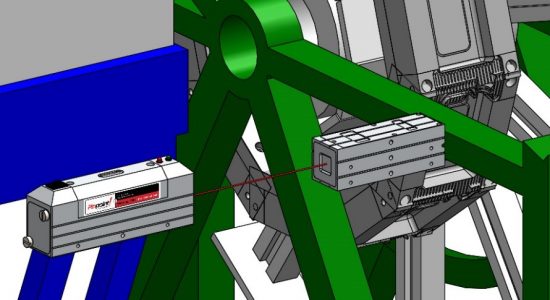

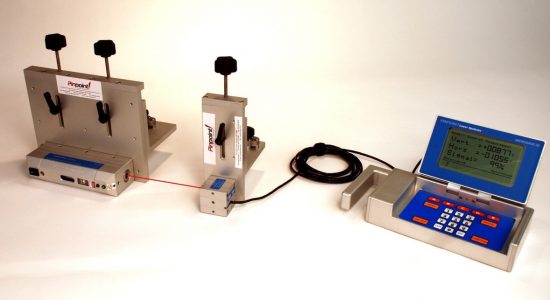

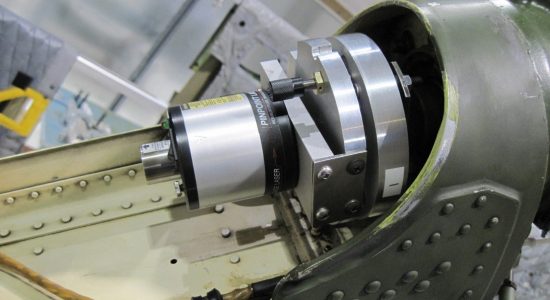

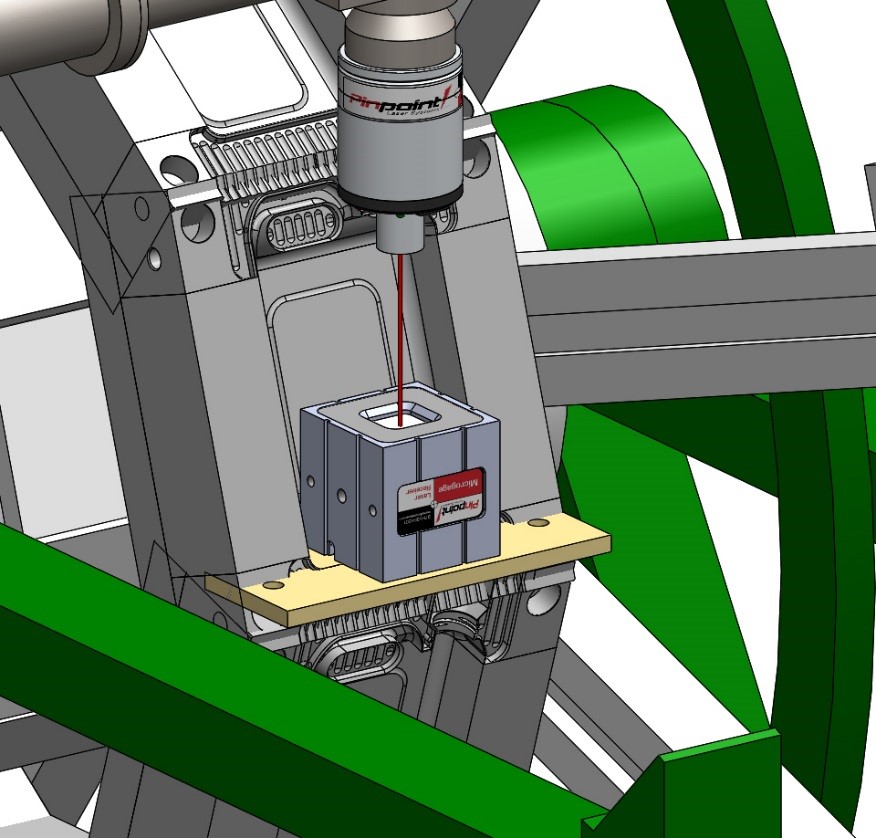

Samples of Our Custom Alignment Equipment

A range of technologies are available for OEM applications, and Pinpoint’s engineering staff is available to configure custom alignment laser solutions to meet your needs. Our proven engineering designs and current purchasing volume for Pinpoint components allow for cost-effective pricing on OEM subsystems.

We have many accessories that can be combined to provide the best custom alignment laser solution for your application needs. To find out more about developing a specific application solution, please contact our engineers here at Pinpoint.

Browse our gallery of custom alignment solutions. Click image to view full size.

What Our Customers Say

One thing that stands out and has been commented on by all who have seen the equipment is its design and build quality. It is a beautifully engineered and built piece of equipment, which is a pleasure to use. Well Done!

Nenad Sarcevic — Airbus UK

Areas of Expertise

- Engineering for full system design

- Customized laser light sources

- Design modifications for receiver housings

- Engineering for fixtures & mounts

- Optical system design

- Software design & development

- Data analysis & routines

- OEM sub-system development

- Sheave and pulley alignment systems

- Bore alignment products

- Profiling systems

- Precision angle positioning

- Runout and alignment checking systems