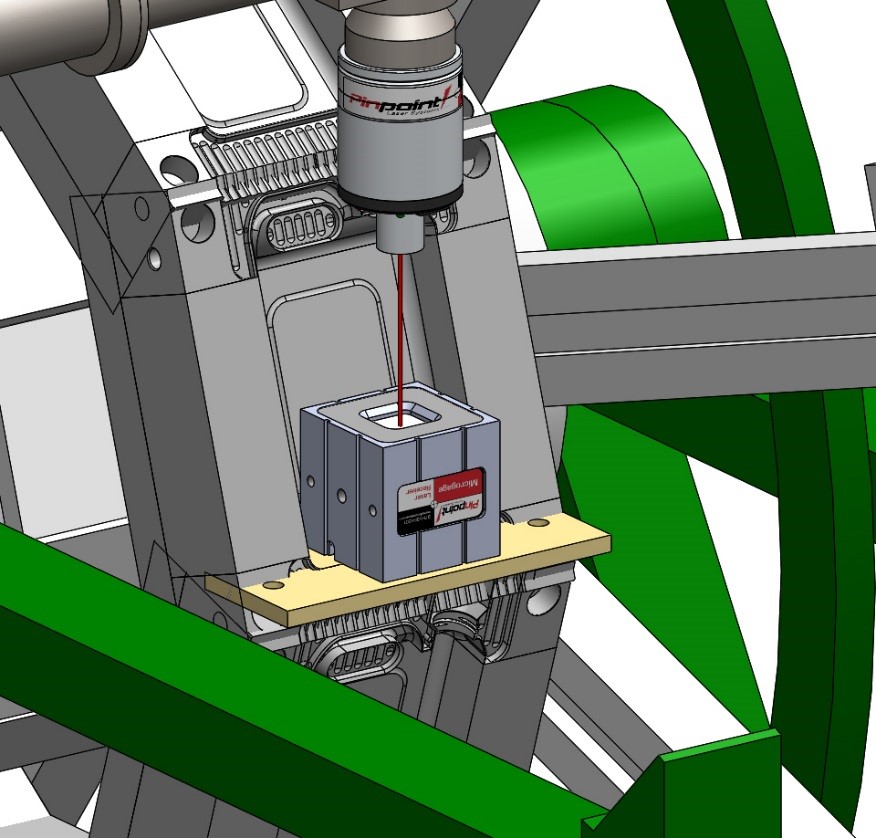

Custom Alignment Equipment

Work with Pinpoint Laser Systems to develop special solutions for your applications and product needs.

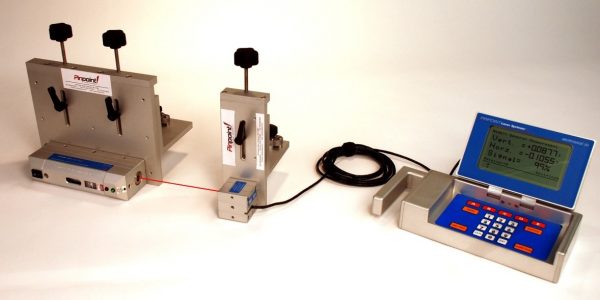

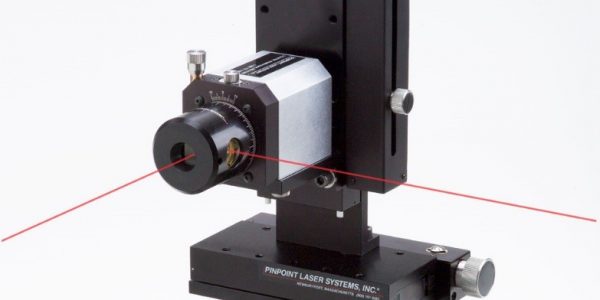

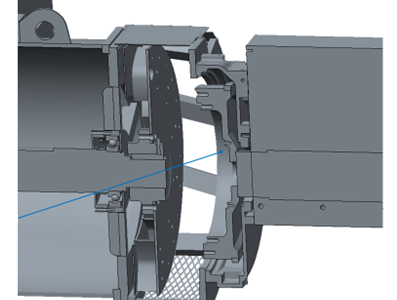

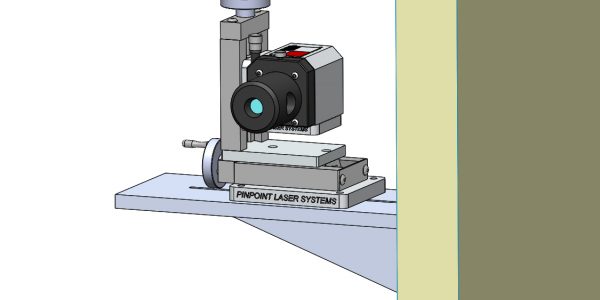

Pinpoint Laser Systems offers a range of technologies for OEM applications and will work with you to configure custom alignment laser solutions that have been tailored for your needs. Our proven engineering designs and current purchasing volume for the components allow for cost-effective pricing on OEM subsystems.

Combine our many accessories to create the best custom alignment laser solution for your application needs. For more information, browse our gallery of custom alignment solutions. Just click on an image to view the full size.

What Our Customers Say

“The sales department was very knowledgeable and the technical department was very thorough. The Microgage 2000 was exactly what we needed for measuring flatness, parallelism and other applications. We are extremely happy with the results. The quality of the parts we received is of the highest order and the accuracy of the measurements is truly spectacular.“

Dr. Joshua R. Williams, Senior Scientist | XStream Systems, Inc.

“This is just an update for you and a testimony to the great help that your product was in assisting us during our installation and maintenance work and shutdown periods. We installed the wedge blocks with ease and they performed in the very same manner. Great product!“

Jeffery W. Evans | Westinghouse Electric Co., LLC

“We purchased the Microgage 2000 Universal Kit to align a test apparatus so that the floor of the test tank and the left wall are straight down their respective lengths of 80 feet to 0.0002 inch or better. The floor and left wall also had to be perpendicular to each other. The laser system worked extremely well and the installation went as planned within the tolerances. Our customer was very pleased.“

Drew Disney, Project Coordinator/Quality Assurance Manager | Hewitt (Brockville) Ltd.

Areas of Expertise

- Engineering for full system design

- Optical system design

- Software design & development

- Data analysis & routines

- Optical system design

- OEM sub-system development

- Sheave and pulley alignment systems

- Bore alignment products

- Profiling systems

- Precision angle positioning

- Runout and alignment checking systems