Mounts

You can take advantage of the Pinpoint Laser Alignment System by utilizing our expansive line of mounts. These mounts are designed to make it easy to accomplish a wide array of alignment applications and projects such as spindle alignment machine leveling and straightness and linear measurement.

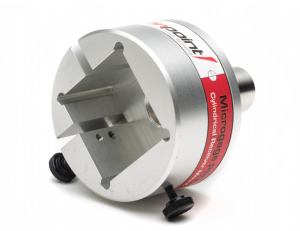

The versatility of the Pinpoint Laser Microgage system is enhanced by our variety of mounting fixtures that are available for securing the system components directly to your machinery and equipment. If you are in need of bore mounts for bore alignment to the roller mounting plate for roll alignment Pinpoint Laser Systems will work with you every step of the way to make sure your laser alignment system is perfectly set up.