Shaft Alignment

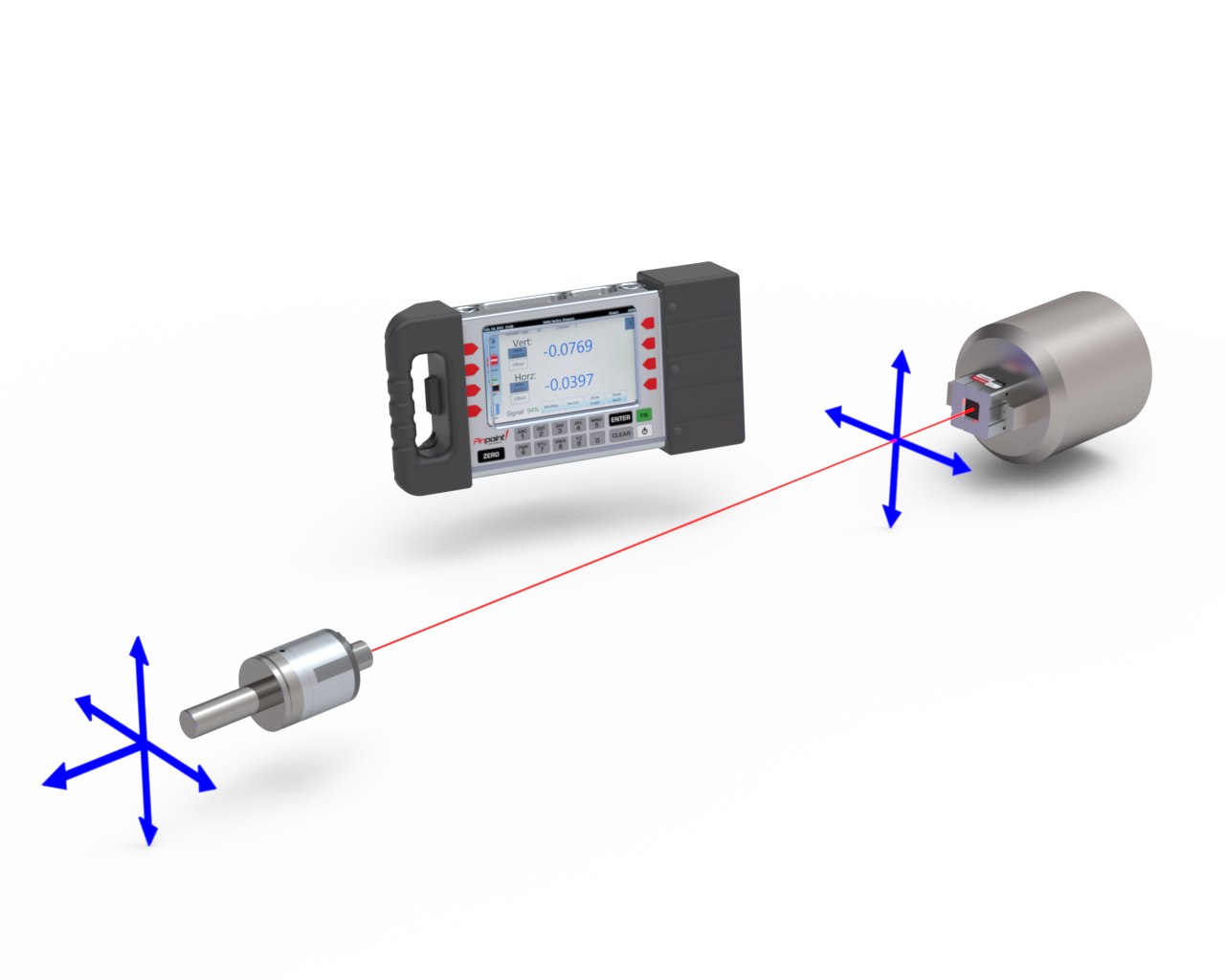

Shaft Alignment can be easily and accurately done with our Laser Microgage System

How it works

This alignment kit uses a laser mounted on machinery, a drive shaft flange, or an assembly and projects a laser reference beam along the shaft line. This reference beam can reliably travel up to 120 feet to an opposing shaft flange or gearbox for alignment. A digital receiver is then used with the reference beam to position bearings, shaft supports or other shaft assembly’s along this reference line. A digital display stores readings, runs computations, and be connected to a laptop or PC for storage and charting.

Typical shaft alignment applications

- Aligning propeller shafts

- Positioning rudder posts

- Shaft and drive alignment

- Installing helicopter drive shafts

- Aligning engines in locomotives

- Aligning turbine shafts in hydroelectric facilities

- Adjusting drive shafts and gear boxes

Components Needed

- Microgage PRO Plus or Microgage 2D

- Plastic Targets for Rough Alignment

- Additional items may been needed based on ship design

Useful Accessories

- Microgage 4D Receiver

- 4-Axis Mount

- Tripod Mount

- Adjustable Magnetic Receiver Base

- Laser Support Stand

- Receiver Extension Cable

Find your solution here

Not sure which laser alignment product is right for your job? Get expert advice from our engineers, contact us today.