Spindle and Lathe Alignment

Laser spindle alignment is ideal for boring, milling, or any head and tailstock turning center equipment. A fast and accurate way to align spindles and lathes.

How it works

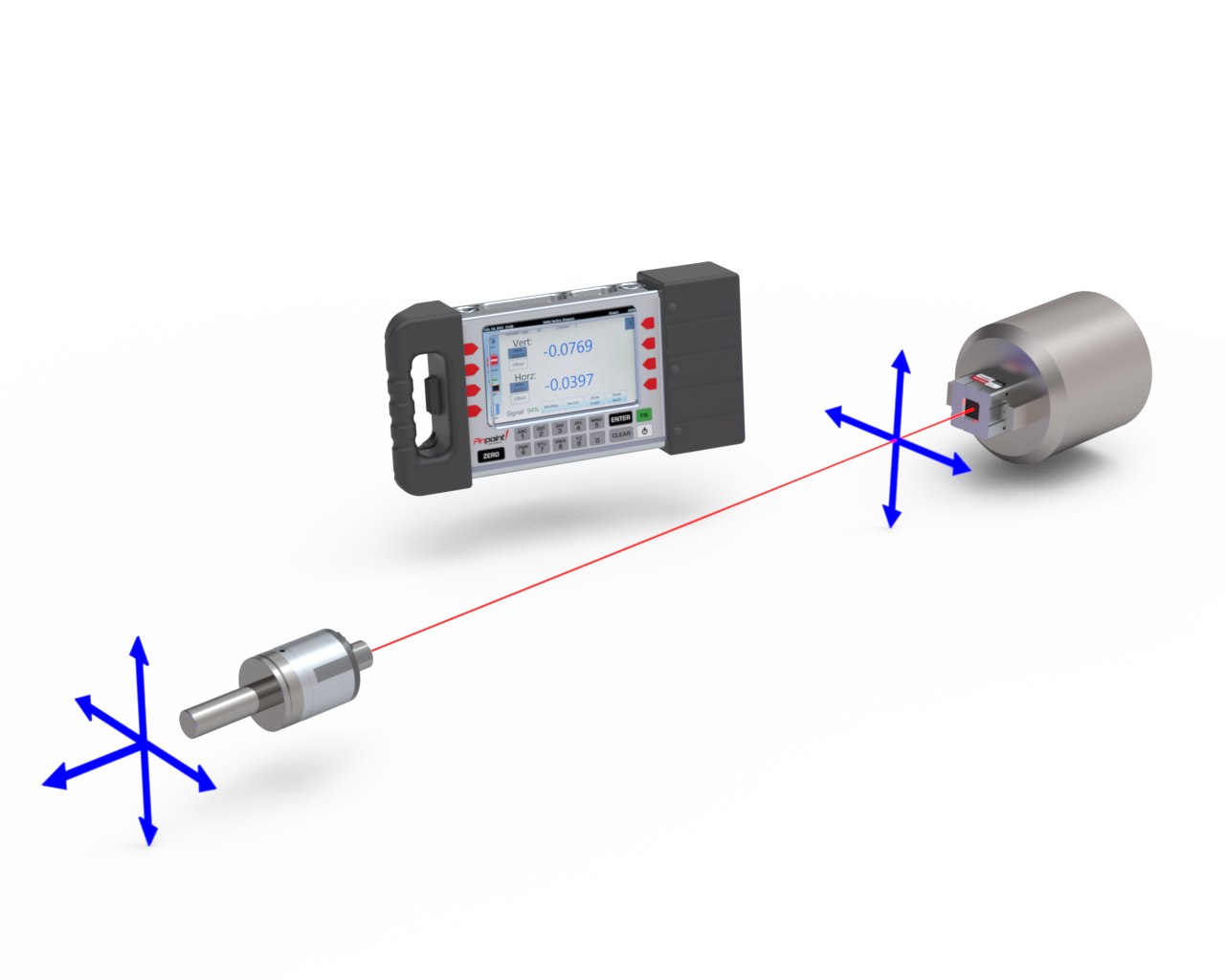

Pinpoint has a spindle alignment kit with accessories to choose from. A cylindrical laser that comes in a variety of models takes these measurements. The laser transmitter is round and placed into a chuck or in the bore of the spindle so that the laser beam is projected along the rotational centerline of the machine. The Microgage receiver is secured to the tool holder, tailstock or mounted in the bore of an opposing spindle to catch the laser beam.

Through a series of simple steps involving turning the laser transmitter and then turning the receiver, readings are taken that show if the spindles or the lathe head and tailstock are on centerline, and if they are parallel to one another and other alignment parameters from a few inches to 65 feet or more. Lathe Alignment can be made over short or long distances.

Typical spindle measurement applications

- Check and align lathes and turning centers

- Position and adjust opposing spindles

- Measure alignment of boring mills

- Position and adjust precision bar feeders

- Other related alignments

Components Needed

Useful Accessories

- Microgage Spindle Alignment Kit

- Special inserts for mounting

Find your solution here

Not sure which laser alignment product is right for your job? Get expert advice from our engineers, contact us today.