Machine shops and many industrial facilities utilize linear stages, X-Y tables, slide tables and other precision motion systems for positioning parts. In some cases, these moving systems carry a cutting head or a read/write system, or similar device used in a carefully controlled process. The question always comes up; “Is this stage running straight and true?” Traditional, measurements of stage runout require expensive optical systems, time consuming techniques, or dial indicators that introduce a variety of error sources.

The Laser Microgage is a perfect tool for measuring runout on a variety of moving stage and slide systems. Recently, we traveled to a customer’s facility and measured the runout on a CNC machining center with an X axis stage that travels 70 inches. The technique and results were interesting.

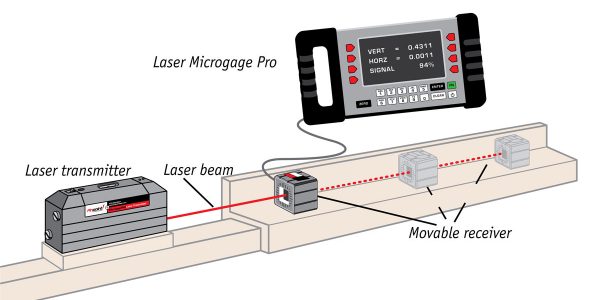

We began by positioning the laser at the end of the machining center and aiming the laser right down the top of the X-axis table. The microgage receiver was secured to the table surface so that the detector port is vertical because we were looking for vertical errors in the stage travel. The display value was then set to zero. The table was run through its full motion in the X axis and readings were recorded every three inches with the position of the moving table. Once the measurements were taken, they were entered into a spreadsheet program and fitted with a straight line. The deviations from the straight line show the vertical displacement errors in the stage travel. By simply turning the receiver onto its side and repeating the procedure we are able to measure side to side or lateral displacement errors.

What did we find? Over 60 inches of travel, the stage moved with only minor variations in the vertical direction. However, at the ends of the travel range we observed vertical shifts of 0.003 inch or more – most likely due to uneven wearing of the ways or distortion of the bed. Customers can use this information to correct their machines and monitor machine performance over time. When setting-up a machine, the Microgage has proved invaluable in aligning slides and X-Y tables. With the DCU and the Data Capture software, runout measurements can be quickly made to a precision of 0.0005 inch over table and slide runs up to 20 feet.

For more information, contact Pinpoint Laser Systems at (978) 532-8001 and info@pinpointlaser.com.

[formidable id=55 title=true description=false]