Straightness Data Routine

Data analysis and calculations for measuring straightness

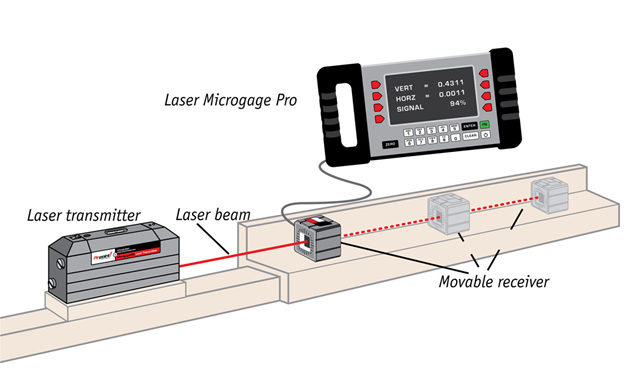

How to Measure Straightness With the Microgage

Step by Step Instructions

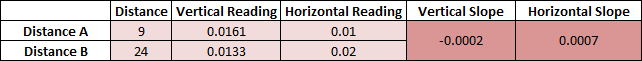

- Place receiver at Distance A, and record readings in table.

- Place receiver at Distance B, and record readings in table.

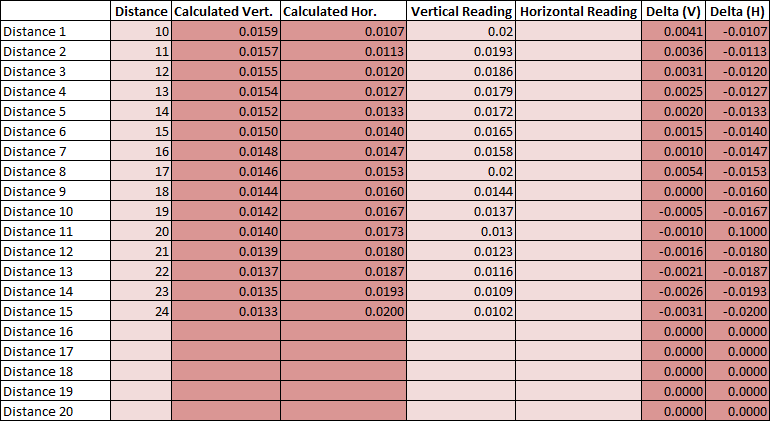

- The calculated rise over run is a factor that can now be applied to any measured distance.

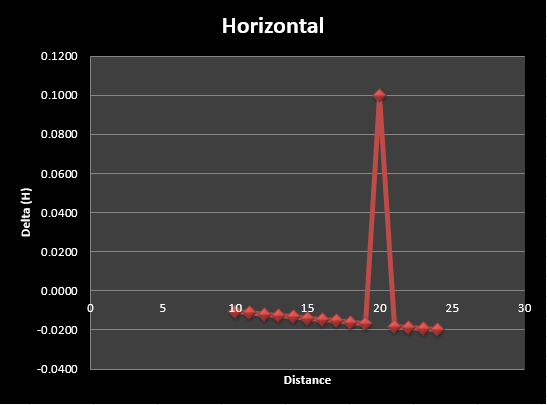

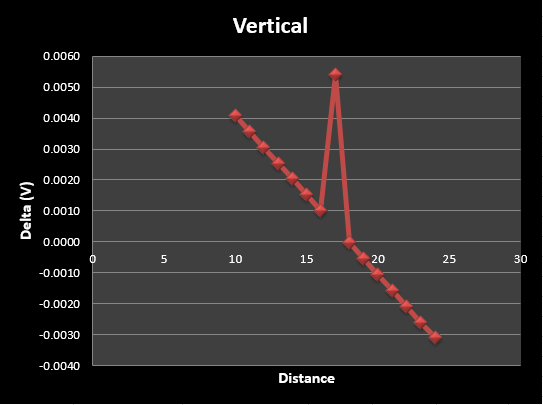

- Record any further measurements in the table in increasing increments of distance, and the deviation from the calculated line will be reported.

Typical Linear Measurement Applications

- Measuring straightness of long machine beds

- Checking for runout on moving slides, tables and stages

- Measure bend and profiles in tracks and guide rails

- Shaft and drive alignment

- Positioning bearings and shaft supports over long runs

- Monitoring surface deflections and bending in long structures

- Aligning long rail and track sections

- Checking roll flatness and profiles

- Measuring deflections on rams, actuators, and extrusion presses

- Other measurement of linear deflections