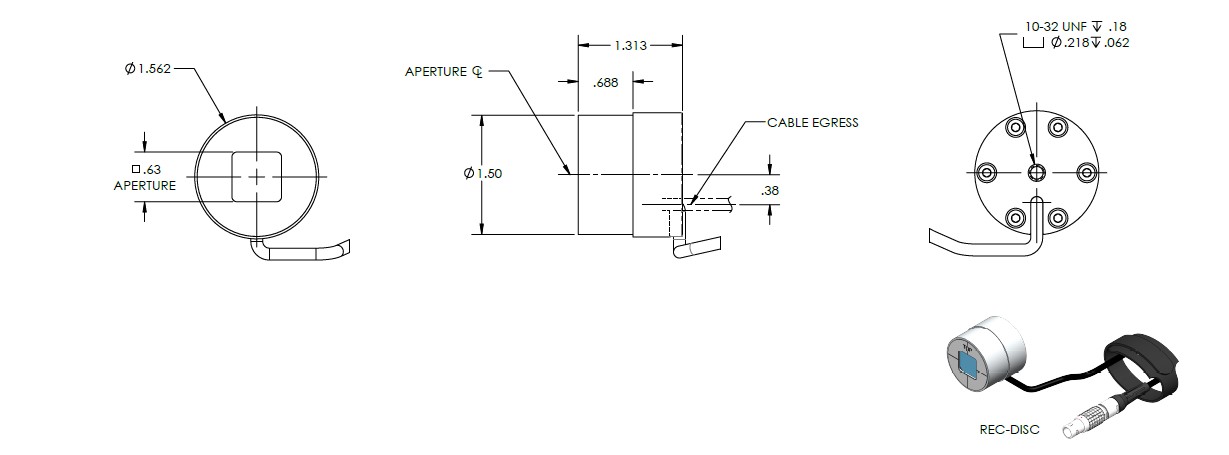

About the Microgage 2-Axis Disc Receiver

The Microgage 2-Axis Disc Receiver is compact and will fit into small places for bore alignment, checking extruder barrels, shaft bearings, and much more. The method of operation is simple – a narrow laser beam provides a measuring reference line and this receiver will determine the X – Y position of a machine or sub-assembly

relative to the laser reference beam. The receiver will operate over a distance of 120 feet or more and deliver a measuring precision of 0.0001 inch. A variety of mounts, tapered shanks, and fixtures can be affixed to this receiver, increasing its versatility for many applications.

The Laser Microgage system and the Disc Receiver are well suited for lathe and spindle alignment, checking bores and extruder barrels, aligning journals, rams and pistons,

Microgage 2-Axis Disc Receiver

- Measuring sensitivity of 0.0001 inch

- Works anywhere along a 120’ laser line

- Operates in any orientation or position

- Durable cable and connector

- No moving parts

- Minimal calibration

- Solid, machined aluminum housing

- 1 year product warranty

- Aligning machine tools

- Bore and extruder alignment

- Positioning ram and shaft runs

- Checking runout on CNC equipment

- Measuring spindle and lathe alignment

- Centering 90 line

- Engine bore alignment