Microgage PRO

Microgage PRO Plus

Microgage 2D

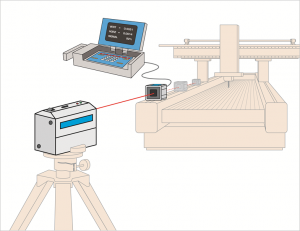

Pinpoint Gantry Kit

Complete laser kit for alignment of 3-axis CNC gantry systems.

The Pinpoint Laser Systems 3-Axis Gantry Kit provides a powerful, cost-effective solution for aligning X-Y tables and 3-axis gantry systems. It measures straightness, flatness, squareness, and level over longitudinal travel of 150’ and more. The kit provides a fast and easy method for achieving precision alignment of gantry machines. Its straight and weightless laser beam replaces traditional references of piano wire, heavy steel straight edges, and granite. Use the measurement values directly to make machine adjustments, or upload your data to a PC for display and further computation and compensation.

Measures all key alignment parameters on 3-axis gantry systems.

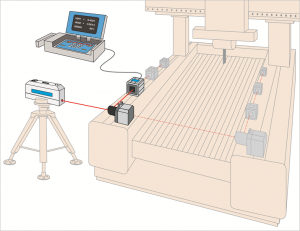

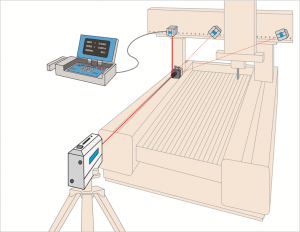

The key elements of the 3-Axis Gantry Kit are the laser transmitter, two-dimensional electronic receiver, and 90-line beam bender. When used with the included remote processing unit and mounts, this kit can handle a comprehensive set of alignment checks, including:

- Straightness of longitudinal rails

- Parallelism of longitudinal rails

- Straightness of cross bridges

- Straightness of Z-axis slides

- Squareness between rails, cross bridges, and Z-axis

- Flatness of tables and beds

- Leveling of machines

Common Gantry Applications

For use at the OEM, or in the field.

- OEMs will appreciate the Pinpoint Gantry Kit during machine fabrication and assembly. Ensure rails are straight and parallel and beds are flat before the gantry leaves your facility. You can even check in-coming parts.

- Installers will appreciate the Kit during initial set-up. Ensure all alignment parameters are in spec before handing off to your customer.

- End users and alignment service bureaus will appreciate the Pinpoint Gantry Kit during repair.

- Check alignment on a regular schedule to detect wear trends for preventative maintenance.

A gantry kit from Pinpoint Laser Systems pays for itself.

Compared to conventional methods, such as wire and cumbersome straight edges, laser systems from Pinpoint can perform alignment checks much more quickly. Plus, a laser delivers consistent, accurate data—even when used by technicians with minimal training.

- Fast: Check an entire gantry machine in hours rather than days

- Easy: Eliminate fussy piano wire or long, cumbersome straight edges

- Consistently accurate: Every technician will get the same results

Characteristics and functions

- Measure straightness, parallelism, squareness, and flatness

- Anodized aluminum housings ensure ruggedness and precision

- Display resolution of 0.0001”

- Accuracy of 0.001” over 100’ distance

- Level to 10 arc-seconds

- Expandable with other Pinpoint accessories

- One year warranty and support

- Interfaces easily to a computer

- Compact and extremely portable

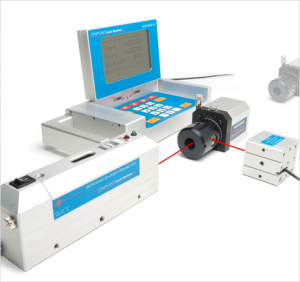

A complete system includes:

- Microgage Laser Transmitter

- Microgage 2-Axis Receiver

- Remote Processing Unit and Display

- 4-Axis Precision Mount

- Leveler Rotational Mount

- 90-Line Right Angle Beam Bender

- Precision Tripod Mount

- Magnetic On/Off Mounts

- USB Interface & Capture Software

- AA Batteries for Laser and Receiver

- Operations Manual

- Rugged Carrying Case

- 1 year warranty

- Free support online or by phone

- Optional: on-site training

Talk to our alignment specialists

[formidable id=16]Talk to our alignment specialists

[formidable id=16]

News & Information from the Trusted Laser Alignment ExpertsPinpoint Laser Systems Manufacturing Customers Include: