About the Verticle Roll Adjuster

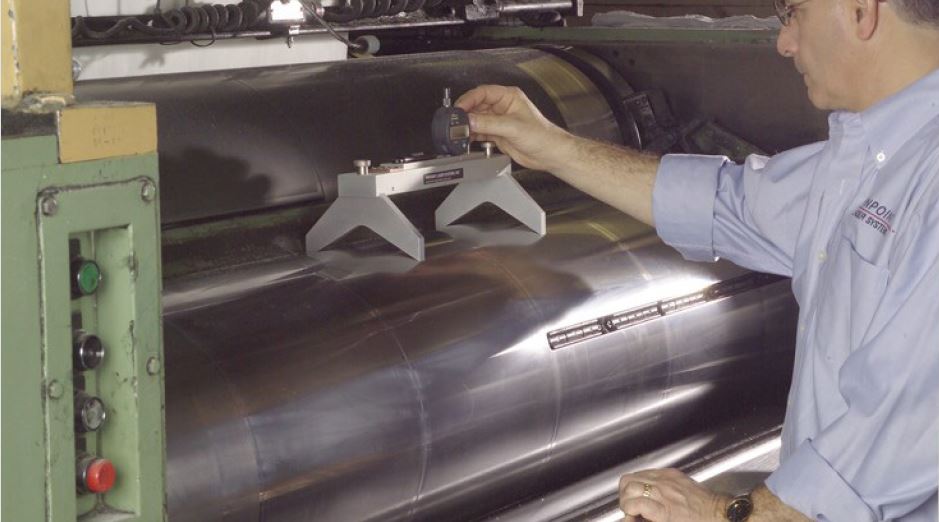

This specialized accessory provides a precise digital readout of a roller’s vertical orientation. The Roll Adjuster is easy to set up by simply placing the mount onto the top of a master roller, driveshaft, or idler, and is held in place by a pair of V-legs or adaptable mounts. A fine adjustment screw is turned until the precision bubble level is centered in its glass vial. The digital micrometer is zeroed by pressing a small button to capture the digital position of this first roll or shaft. The Roll Adjuster is then moved to the top of the next available roller and the fine adjustment screw turned until the bubble level is again centered. The vertical alignment of this second roller, relative to the first, is shown digitally, either in inches or millimeters, allowing for more accurate adjustment or selection of shims. The Roll Adjuster is moved to successive rolls for additional measurements and adjustments through the length of the machine.

The Roll Adjuster is machined from solid aluminum with stainless steel parts and interchangeable mounting feet for added versatility. A storage case is included.

Verticle Roll Adjuster Details

- Easy to set-up and use

- Precise digital output to 0.0001”

- Works on large and small rolls alike

- Interchangeable mounting feet

- Accurate to <0.001” per 12”

- Machined from solid aluminum

- 1 Year Warranty/Product Support

- Paper mills

- Converting lines

- Printing presses

- Plastic bag lines

- Coating lines

- Other roller and web applications