If bore alignment feels closer to hog tying than checking up, down, left and right, this information is for you no matter what your job or industry. Even our most prominent clients in fields such as ion implantation and robotics struggle with finding the tightest tolerance needed. A task as simple as keeping extruder barrels aligned in a plastic molding plant often results in a quality manager calling for help.

If bore alignment feels closer to hog tying than checking up, down, left and right, this information is for you no matter what your job or industry. Even our most prominent clients in fields such as ion implantation and robotics struggle with finding the tightest tolerance needed. A task as simple as keeping extruder barrels aligned in a plastic molding plant often results in a quality manager calling for help.

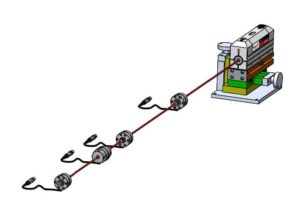

Aligning extrusion presses and bar feeders, or propeller shafts and stern tubes doesn’t have to be a hassle. Experiential knowledge and the right toolkit are essential to moving your work along without the rookie mistakes and hiccups that set your team back hours, if not days. The best way to hit the factory floor running is to use a quick setup,

simple to use laser alignment tool.

The Microgage Bore Alignment System is an excellent example of such a simple yet reliable tool. In addition, the laser alignment receiver unit makes bore position readings easier to work with and measures in increments as small as .0001 inch over ranges of 150 feet.

Need an example?

Need an example?

Let’s say your team builds aircraft and spends a lot of time dealing with carbon fiber composites that get bonded onto a titanium fitting pre-assembly. If the “finished” section of the project your building needs aligned holes, the layer of materials that gets attached benefits greatly from custom bore alignment in order to obtain proper fit. A laser alignment system can insure that the pins and their respective bushings are aligned onto a common centerline and that the walls of the pin and bushings are precisely parallel.

Any component or part, which must receive concentric alignment, requires a defined straight line from one end of a fixture to the other. Be the line 1” or 101” away, the precision of the line can mean the difference between getting your measurements right the first time and not relying on the trial and error approach.

Because multiple bores can now be measured in one operation with Pinpoint Microgage laser systems, some engineers will multi-task, using customized fixtures and accessories for bore alignment with bushings. Pinpoint Bore Mount Receivers can be configured to fit into large and small bores ranging in sizes from 3/8” (0.375 inches) to 1 ½ inches and larger. Having the ideal laser system for checking straightness of a 10mm bore or tube will surely save time and alignment tasks effort in the long run.

Instead of wrangling with archaic piano wire and other out dated “tools” for proper alignment, your business focus should be on work quality, not potentially inaccurate, cumbersome, outdated techniques. While you may not be boring through the Chunnel, your work is important. Take a minute to invest in dimensional measurement systems that work as smart as you do.