Pinpoint Laser Systems Introduces Its Newest Capture Software.

Enhanced Features Mean More Convenience, More Power.

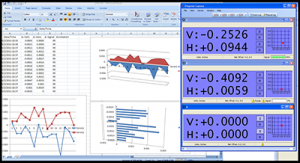

Pinpoint Laser Systems has introduced a new and improved data accessory named “Pinpoint Capture™” for the popular Laser Microgage industrial measuring and alignment system. Pinpoint Capture™ allows operators to quickly grab measurement readings, on the fly, from as many as four remote laser receivers to analyze the alignment and performance of their production machinery and industrial equipment. The software is a powerful, Windows-based application that quickly records incoming readings, displays results and enables added control. It interfaces cleanly with spreadsheets, statistical analysis packages and other programs. Capture™ allows measurement readings to be stored directly in the handheld, portable Laser Microgage display and then uploaded to a PC or laptop or routed directly to the PC or laptop for analysis, printing and storage. The Laser Microgage armed with the new Capture™ software is easy to use and highly versatile, delivering a precision of 0.0001 inch (0.0025 mm) over a working range of 180 feet (55 meters).

The new Pinpoint Capture™ software brings a wide host of new capabilities to industrial alignment and measuring. The program collects and displays measuring readings from up to 4 laser receivers placed on machinery. These displays can be customized for specific user alignment and measuring applications. A built in spreadsheet function allows for easy computations on incoming readings and additional graphing and plotting capabilities. A step by step instruction feature gives users an active recipe to follow for popular alignment routines on industrial machinery. Pinpoint Laser Systems has also installed standard measurement and alignment routines that are versatile, quick and easy to follow for general alignment tasks such as spindle and lathe alignment, machine tool runout checks, and other common applications. Laser Microgage measurements can be stored automatically with many readings per second or can be recorded over time individually by the user with notes.

The new Pinpoint Capture™ software brings a wide host of new capabilities to industrial alignment and measuring. The program collects and displays measuring readings from up to 4 laser receivers placed on machinery. These displays can be customized for specific user alignment and measuring applications. A built in spreadsheet function allows for easy computations on incoming readings and additional graphing and plotting capabilities. A step by step instruction feature gives users an active recipe to follow for popular alignment routines on industrial machinery. Pinpoint Laser Systems has also installed standard measurement and alignment routines that are versatile, quick and easy to follow for general alignment tasks such as spindle and lathe alignment, machine tool runout checks, and other common applications. Laser Microgage measurements can be stored automatically with many readings per second or can be recorded over time individually by the user with notes.

Pinpoint’s Laser Microgage System is used across many industries for checking the alignment of production machinery and equipment. The precise laser reference beam is ideal for checking straightness, flatness, squareness, parallelism, bore alignment and many other geometrical parameters. Pinpoint products are designed and manufactured in the United States and incorporate durable, solid metal packaging, stainless steel components and quality glass optics for years of reliable use on the factory floor. A wide assortment of accessories enables users to adapt their Laser Microgage to new applications and reduce their dependence on outside alignment contractors.

Since 1992, Pinpoint has offered a broad line of alignment and measurement laser systems that are easy-to-use, versatile and portable. These products are designed to pay for themselves quickly by decreasing manufacturing downtime and increasing product quality. The laser alignment tools are used for both routine and complex measurement and alignment tasks, delivering measuring resolution of 0.0001 inch and working over ranges of 180 feet. Pinpoint’s aligning equipment is actively used in a diverse range of industries, including aerospace, aircraft, machine shops, paper and textile mills, shipbuilding facilities, medical scanning equipment, extrusion plants, and electronic assembly facilities, to name a few. Pinpoint offers customized solutions, working closely with manufacturers to engineer specialized products for their unique applications.