You never want to hear a plant manager yell, “Stop the line!” It most likely means that the machine is out of alignment or defective product is coming off the line. Perhaps a thin film is being drawn too tight on one side and is wrinkling, or the material running through the machine is not tracking straight and wandering off the edge of the machine. Needless to say, production has just shut down costing you time, money, and perhaps angry customers.

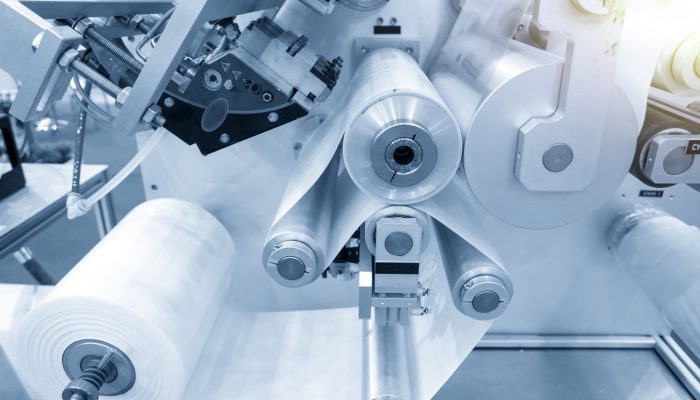

Many manufacturing facilities operate equipment that contains rollers, idlers, nip rolls, payoff reels, rewind rolls, accumulators, and web handling systems. The alignment of roll and web systems is important to the efficient operation of these systems to improve productivity and reduce production downtime.

One very common industrial application of laser alignment equipment is verifying the position and alignment of rolls and web handling equipment. In these applications, there may be many rollers over which material passes as it proceeds through a specific manufacturing process. An example is a laminating operation in which a substrate such as pliable plastic or metallic foil is treated and coated as it passes through a process line. If the feed rolls, or payoff reel and the rewind rolls, at each end of the line are not well-aligned, the material will not track properly and may wander off the machine resulting in downtime and wasted material. Rolls in the middle of the laminating line, such as nip rolls, idlers, chiller rolls and others can also contribute to misalignment and influence the tracking and quality of the product moving through the machine.

Misalignment of the rolls through the machine may not be enough to cause tracking problems, but may still stretch the material more on one side than the other, which means that it is likely to be rejected for poor product quality.

For a continuous sheet of material moving through a system of rollers, it is critical that the left edge, center, and right edge follow similar path lengths- a misaligned roll anywhere in the system may cause stretching of the material at that location. Some plastic materials are highly compliant and will spring back, so roll alignment is less critical here. Other materials such as copper foil, Kevlar films, and metalized substrates are less forgiving and if stretched across misaligned rollers may be permanently deformed and will not regain their original dimension. For these reasons, the alignment of roll systems is very important and a laser alignment system is an ideal tool for this task.