The Microgage PRO Plus is the next generation in laser measuring and alignment tools. Simplifying the inspection and alignment process, the microprocessor uses Smart data technology to equip its user with step by step instructions and easy to use data giving you the answers you need. This extremely versatile measuring and alignment tool combines key features and capabilities into one portable, compact, easy to use, product for multiple industries.

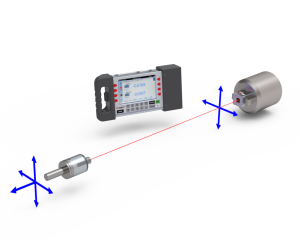

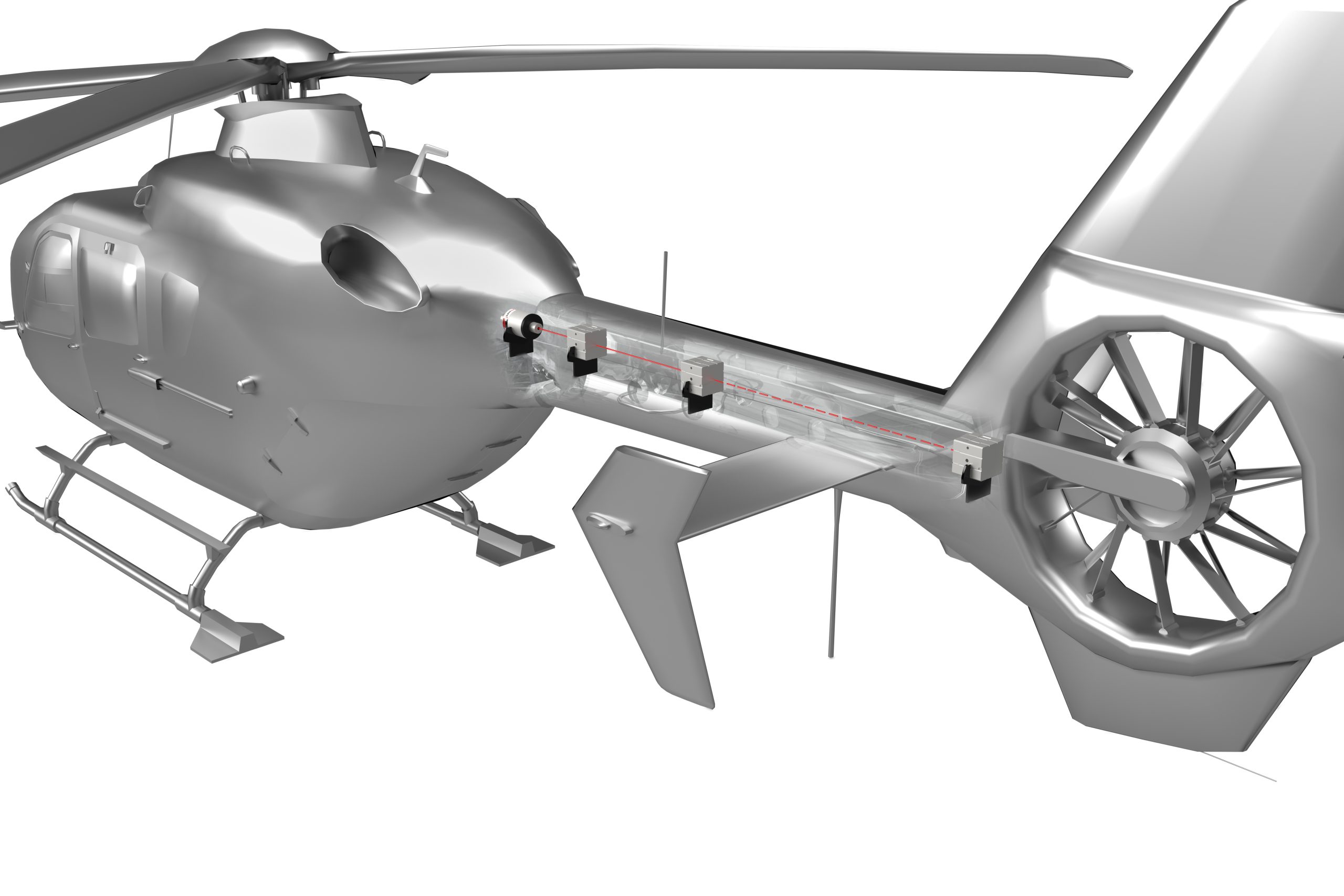

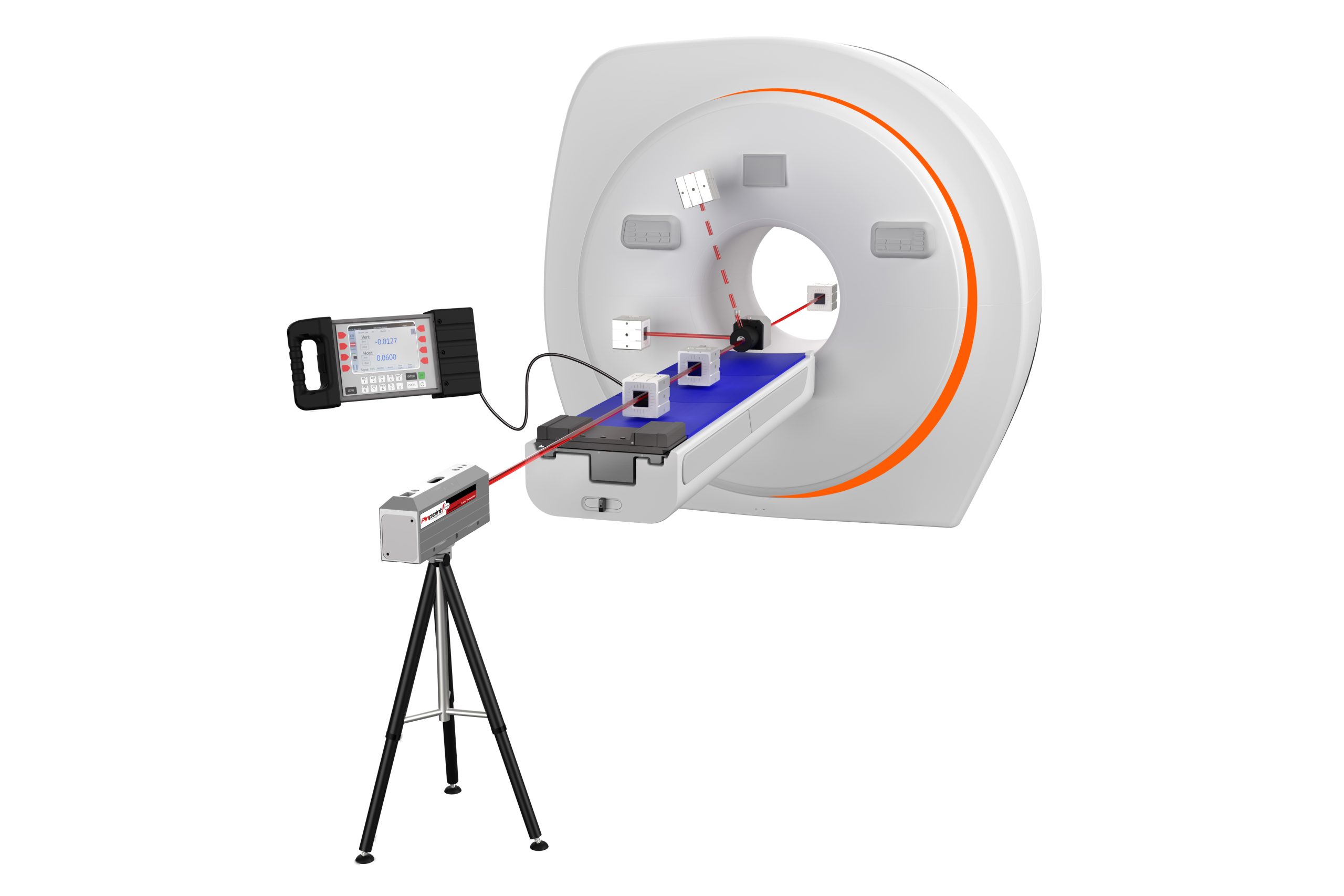

Microgage PRO Plus works on a very simple principle: Laser light travels in a straight line. If you attach a laser transmitter to one assembly and a laser receiver to another, then the alignment of the two assemblies will equal the X/Y displacement of the laser beam at the receiver. And Microgage PRO Plus measures all this with a precision of 0.0001 inch over distances of up to 165 feet.

What Is Included

Every Microgage Pro Plus comes with the following items to make a basic system, while the basic system works flawlessly out of the box we provide a large variety of tools and addons to help you complete any alignment need.

- Microgage PRO Plus Smart Display Unit

- Microgage PRO Plus Laser Transmitter

- Microgage 2-Axis PRO Plus Receiver

- Adjustable Receiver Mount

- Magnetic On/Off Mount

- A/C Power Supply

- Computer Interface Cable

- Pinpoint CaptureTM Software

- Manual

- Durable Carrying Case With Foam Insesrts

- 1 – Year Warranty

Alignment Solutions

How It Works

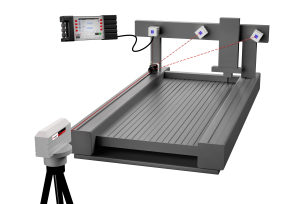

A precise laser beam forms a straight reference line for a machine or assembly and each receiver measures in two axial directions, horizontal and vertical (X & Y). The path of the laser beam can be a few inches up to 180 feet and a state of the art touchscreen display provides accurate readings as small as 0.0001 inch (2.5 micron).

Smart Display

- Bright, high-definition, color readout.

- The digital data of the laser’s position will read “0” for height & lateral readings if laser & receiver rest on the same plane & against a straight guide rail.

- If the receiver is moved, the measurement readings will change accordingly.

- On-board microprocessor provides instructions & stores thousands of measurement readings.

- Durable enclosure

- 20 Hours run time on rechargeable batteries.

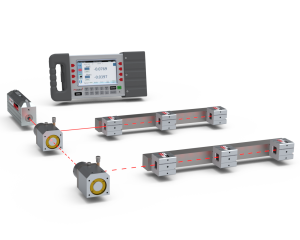

Wireless Capabilities

- Control alignment work without the hassle of running cables and cords.

- The wireless receiver reads the laser reference beam then sends X-Y measurements to the digital display.

- Powered by two AAA batteries.

- Wireless receiver is comprised of durable internal components and solid aluminum housing.

- Resolution of 0.0001 inch (2.5 µ)

- All manufacturing done in the U.S.

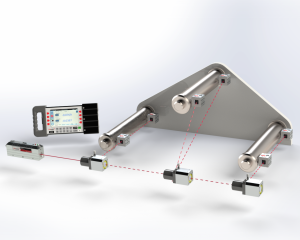

Applications

- Measures most machine geometries straightness, flatness, parallelism, squareness, bores, spindles, and many others.

- Equipment installations, repair, maintenance applications, and much more.

Capture™ Software

- Capture™ is our Windows-based, proprietary alignment software.

- Displays readings in large numerals and with graphical X/Y and moving chart plot.

- Provides real-time measurement data in a customizable Excel format.

- Analyzes industrial equipment and production machinery performance and alignment.

- Works with up to 8 receivers.

- Pre-installed routines and built-in instructions allow Capture™ to interface seamlessly with other packages and programs.

Components

- 3 primary components: Laser transmitter, receiver & display

- Specific application components:

- 90 Line Beam Benders

- Cylindrical Lasers

- Transparent Receivers

- 4 Axis Receivers

- Wireless Receivers

Customization

- Custom receiver housing units

- Laser housings

- Laser light sources

- OEM sub-systems

- Software

Support

The Microgage PRO Plus sets a new standard for ease-of-use and includes user instructions and the operations manual right on board for easy access. In addition, Pinpoint’s well known engineering support team is available for free engineering support when and if you need it.