About Parallelism

Product # – PR-PL41

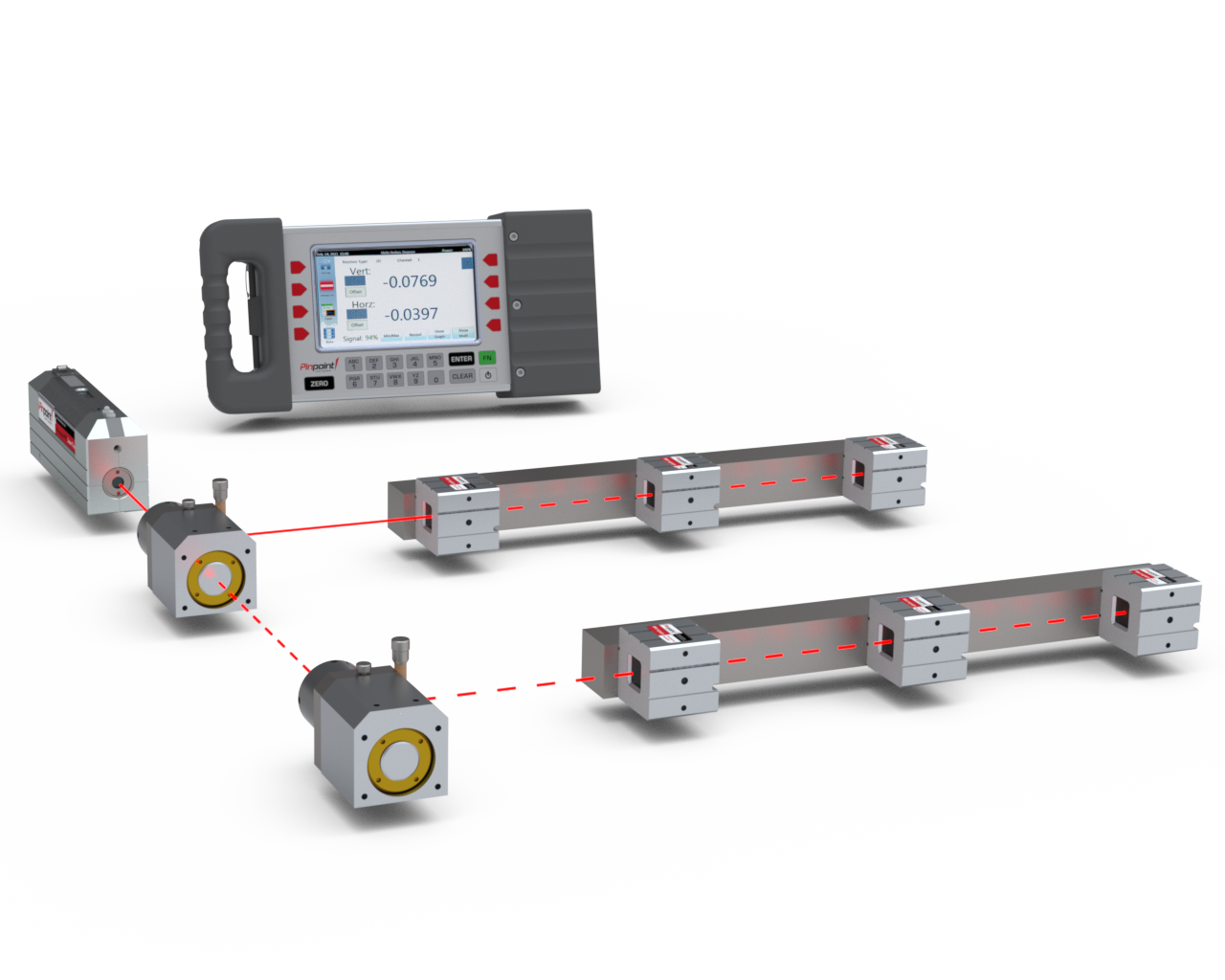

The Microgage system Parallel Kit comes with the Enhanced 90-Line beam redirector which utilizes an internal optical element called a penta-prism that reflects the laser at precisely 90 degrees to the incoming laser beam. For parallelism measurements, the 90- Line is moved sequentially along the laser path to create multiple reference lines, or planes, that are each square to the original laser reference line and parallel to each other. Along each of these individual square reference lines, the Microgage receiver takes a series of readings to see how that surface, shaft, track, or object is = positioned relative to the square laser reference beam. The 90-Line is then moved to a new position, creating another square laser line, parallel to the last line, which measures the position of the next track, shaft, or surface.

Parallelism Details

- PRO Smart display unit

- 4-Axis Precision Mount

- Precision Tripod Mount

- Pinpoint CaptureTM software

- Wireless option for convenience

- Precise down to 0.0001 inch (depending on application)

- Quick return on investment

- Intuitive set up and use

- Improves efficiency and expands in-house capabilities

- Removes guesswork for alignment or measurement

- Minimizes machine downtime

- Supports preventative maintenance efforts

- Eliminates need for outside alignment contractors

- Reduces machinery installation costs

- Measuring and aligning rollers and web handling systems

- Aligning precision tracks and guide rails

- Installing gantry slides and router assemblies

- Checking and aligning pallet loaders

- Align unwind and take up roll sections

- Measuring parallel edges

- Aligning sprocket and drive systems

- Checking columns on injection molding machines

- Plus many other applications

Measuring System

Specifications

Measurement resolution

0.0001″ (2.5 micron

Measurement accuracy

± 0.0002″ or 1% of measurement (5 micron)

Operating distance

6” to 180”

Laser Transmitter*

Specifications

Laser accuracy

≤ 2 arc-seconds

Laser level

10 arc-second, machinist grade

Laser source

laser diode, 636Nm, < 1mW

Laser repeatability

<1 arc-second

Laser dimensions

4.3” L x 2.6” D x 8.1”C

Laser housing

solid machined aluminum, hard anodized coating

Receiver*

Specifications

Active detection area

(0.75″ x 0.75″ 19mm x 19mm)

Receiver housing

solid machined aluminum & hard anodized coating

Receiver dimensions

2.0” x 2.0” x. 20”, 2.0” x2.0” x 3.0” (wireless)

Smart Display

Specifications

Display configuration

hand-held, portable, self-contained

Resolution

0.0001″ (2.5 micron)

Units

inch, mm, mils, custom

Display

state-of-the-art, color, high-resolution, touchscreen

Controls

keypad, multifunction buttons, touchscreen

Storage

data readings & notes up to 10,000

Housing

solid machined aluminum, hard anodized coating