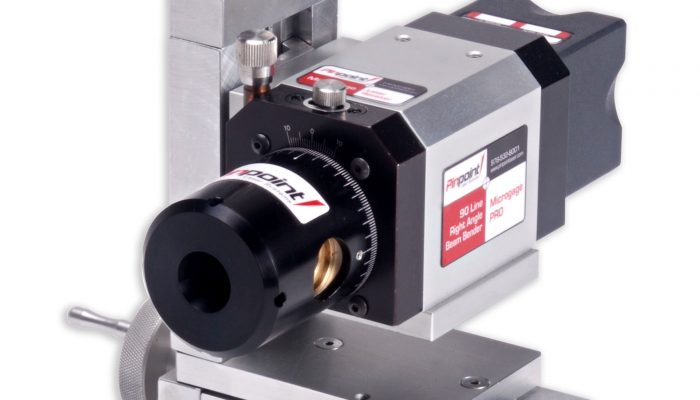

Pinpoint Laser Systems has released a new laser alignment accessory, the Microgage Bore Receiver.

The Microgage Bore Receiver is an innovative solution for precisely measuring the straightness of a tube or bore. The receiver is supplied with sets of interchangeable collars that can be manufactured in different shapes, configurations and  materials depending on the contour or condition of the bore tube. The Microgage Bore Receiver works by being inserted into the bore where it detects a laser reference beam moving through the entire bore. As users move the Bore Receiver through the tube it gathers readings along the way. The Display unit clearly shows the readings in each location along the path and can quickly and accurately detect defects. Using the Pinpoint Capture software, these readings can be recorded and then plotted into a graph.

materials depending on the contour or condition of the bore tube. The Microgage Bore Receiver works by being inserted into the bore where it detects a laser reference beam moving through the entire bore. As users move the Bore Receiver through the tube it gathers readings along the way. The Display unit clearly shows the readings in each location along the path and can quickly and accurately detect defects. Using the Pinpoint Capture software, these readings can be recorded and then plotted into a graph.

Various industrial applications for the Microgage Bore Receiver include measuring the straightness of propeller shaft bores, gun barrels, extruder barrels, engine cylinders, drive shaft bore tubes, and many more.

“The Bore Receiver was developed to meet the demands of our industrial customers, many of whom utilize manufacturing equipment that require flexible, precise bore alignment to improve quality and keep their machines running smoothly. We are very excited to be offering this much demanded and needed product to our customers,” says Mory Creighton, President of Pinpoint Laser Systems.

For more information on this product or other news items, please contact Pinpoint Laser Systems, Inc. at 1-800-757-5383 (US) or 978-532-8001. Or email your questions to rbelt(at)pinlaser(dot)com.