February 2011, Peabody, Massachusetts

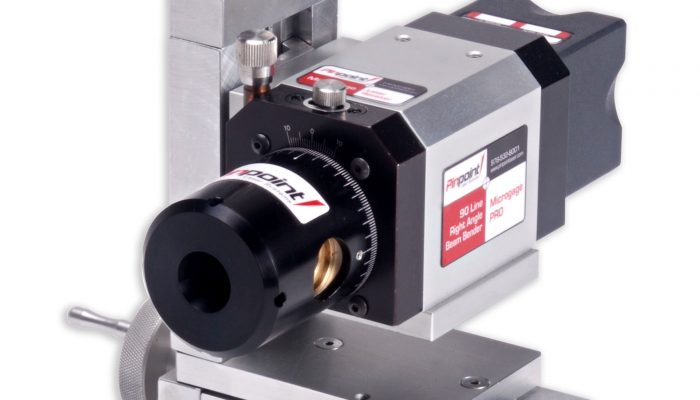

Pinpoint Laser Systems is introducing new and improved version of our 4-Axis Precision Mount for the Laser Microgage line.

The 4-Axis Precision Mount moves the Microgage Laser in four axes; vertical and horizontal, as well as two angular axes pitch and yaw to simplify machinery and equipment alignment tasks. The laser beam can be positioned to within 0.001 inch and is ideal for checking machinery travel, precision bore alignment, the straightness of fixtures and assemblies and much more. Like all Pinpoint products, this mount is easy to set-up and can be used on the production floor, as well as in the field for installations and servicing work.

Two precision micrometers adjust the elevationof the laser up and down, as well as its position left and right. Another pair of precision adjustments are for angular control of pitch and yaw. The mount is easily attached to a tripod or bolted to a machine, allowing for tight laser positioning control over distances as great as 150 feet. This 4-axis mount can be used for checking straightness, machinery parallelism, squareness, flatness, bore alignment, and other demanding alignment tasks.

The 4-Axis Precision Mount is fabricated from solid aluminum and is protected by a hard, anodized coating. The micrometers are graduated in 0.001 inch increments (metric versions available) for easy control, and the mount is assembled with precision roller bearing slides andstainless steel hardware for years of reliable use.

[cta_press]