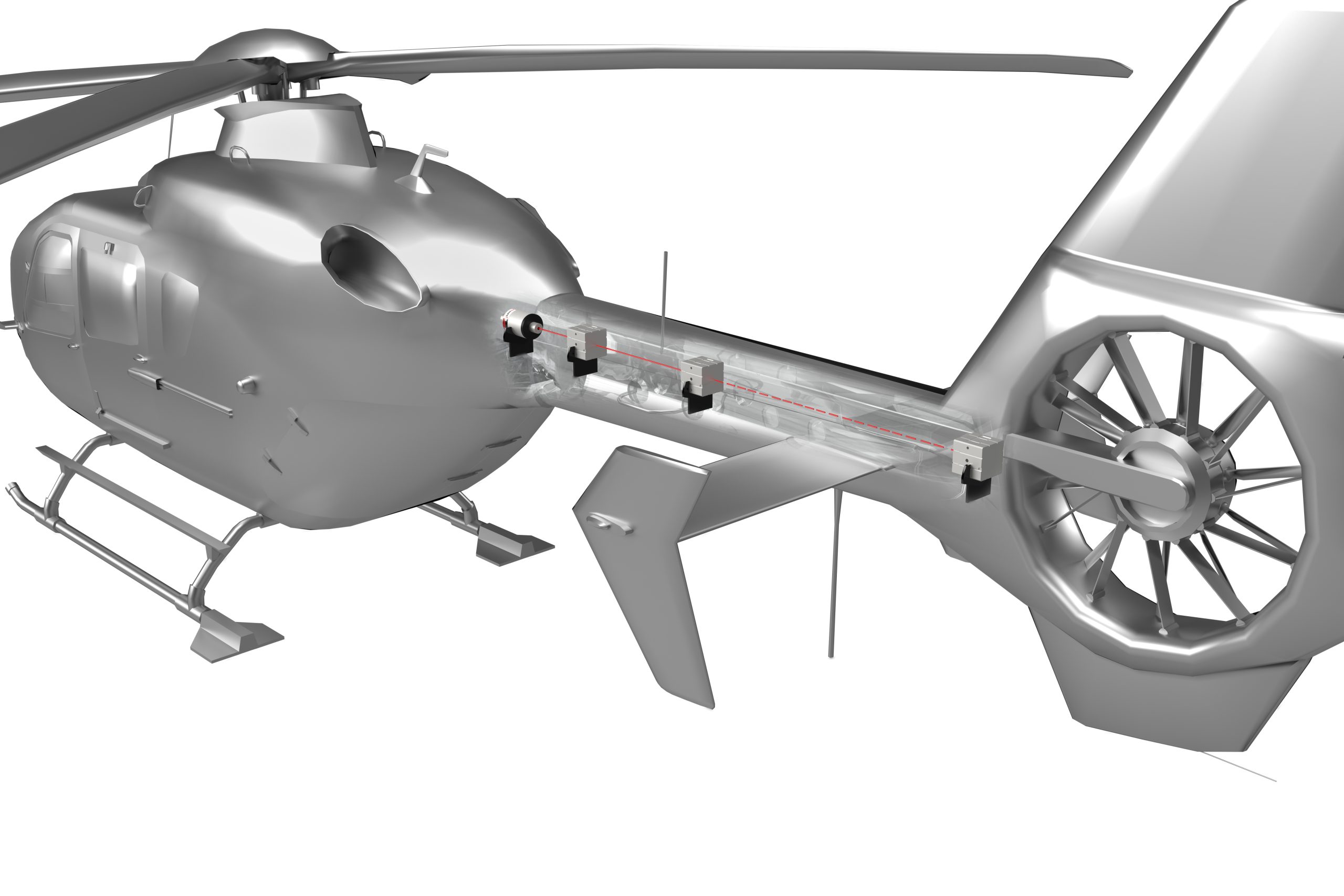

About Helicopter Alignment

The Microgage laser alignment solution is used to replace the traditional wire with a laser beam and a digital laser receiver to preform tail rotor shaft alignment. To start, the laser would be mounted on the plate that is attached to the tail boom when it is removed from the helicopter. If the tail rotor driveshaft system were to be aligned with the tail boom in place, the laser could be attached to the drive phalange on the main gearbox.

Helicopter Kit Details

- PRO Smart display unit

- 4-Axis Precision Mount

- Precision Tripod Mount

- Pinpoint CaptureTM software

- Wireless option for convenience

- Precise down to 0.0001 inch (depending on application)

- Quick return on investment

- Intuitive set up and use

- Improves efficiency and expands in-house capabilities

- Removes guesswork for alignment or measurement

- Minimizes machine downtime

- Supports preventative maintenance efforts

- Eliminates need for outside alignment contractors

- Reduces machinery installation costs

Measuring System

Specifications

Measurement resolution

0.0001″ (2.5 micron)

Measurement accuracy

± 0.0002″ or 1% of measurement (5 micron)

Operating distance

6” to 180”

Laser Transmitter*

Specifications

Laser accuracy

≤ 2 arc-seconds

Laser level

10 arc-second, machinist grade

Laser source

laser diode, 636Nm, < 1mW

Laser repeatability

<1 arc-second

Laser dimensions

4.3” L x 2.6” D x 8.1”C

Laser housing

solid machined aluminum, hard anodized coating

Receiver*

Specifications

Active detection area

(0.75″ x 0.75″ 19mm x 19mm)

Receiver housing

solid machined aluminum & hard anodized coating

Receiver dimensions

2.0” x 2.0” x. 20”, 2.0” x2.0” x 3.0” (wireless)

Smart Display

Specifications

Display configuration

hand-held, portable, self-contained

Resolution

0.0001″ (2.5 micron)

Units

inch, mm, mils, custom

Display

state-of-the-art, color, high-resolution, touchscreen

Controls

keypad, multifunction buttons, touchscreen

Storage

data readings & notes up to 10,000

Housing

solid machined aluminum, hard anodized coating