Custom Gear Box Alignment

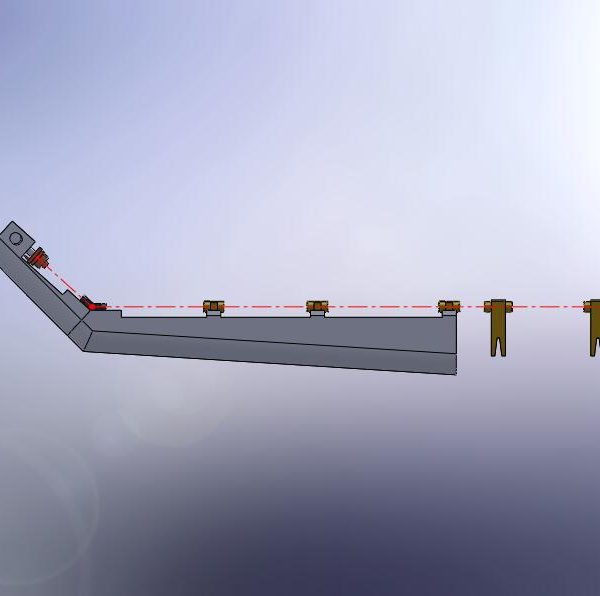

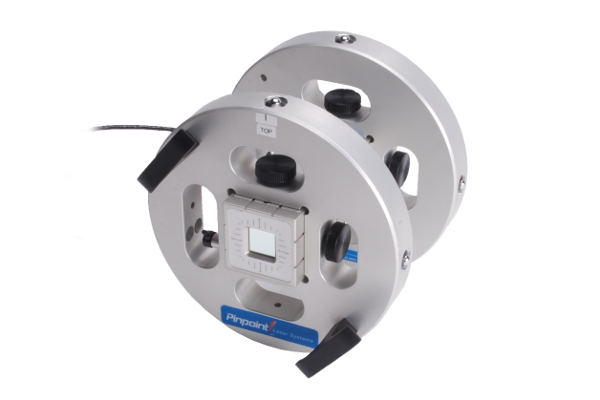

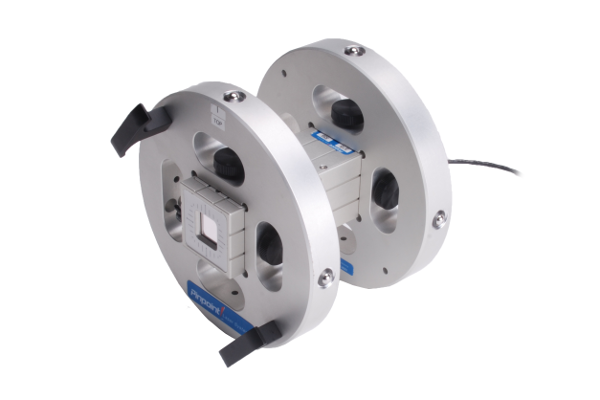

This custom alignment system addresses the alignment of the tail rotor drive shaft system and also to drive shaft system connecting the main gear box to the reduction gearbox on the Bell Griffon helicopter. The traditional alignment technique used on the Griffon involves the use of wire pulled tightly between two endpoints, fixtures with small guide holes and a trial and error approach. One of the shaft sections, for the reduction gearbox, requires the use of a gage bar and a dial micrometer in a confined and limited space and significant numerical analysis to determine corrective alignment action. These approaches are time-consuming, require high expertise, and are difficult to achieve accuracy. Our Pinpoint alignment system uses a precision alignment laser system for aligning the drive shafts on this helicopter.

The Pinpoint alignment system provides precise, quantitative information on the alignment of the gearboxes and the four hanger bearings without removing the tail boom assembly. This Pinpoint alignment system also provides a precise graphical and digital readout to guide the alignment. In addition to the significant improvement in accuracy, the laser approach gives the operator real time, quantitative feedback on their alignment and eliminates the trial and error approach and risk of wire movement or breakage common with wire alignment. The Pinpoint alignment system can be used for periodic checks if necessary to see if a full alignment is even required. Furthermore, this Pinpoint alignment system will reduce the labor hours needed for the alignment and reduce the requirement for a precise “technique” necessary for making the wire approach successful.

The benefits of the Pinpoint alignment system are summarized below;

- Improved alignment accuracy & repeatability for all hanger bearing mounts & gearboxes

- Align gearboxes & Hanger Bearings without removing the tailboom

- Reduce alignment time and personnel required for task

- Digitize alignment results for preventative maintenance & better alignment

- Provide direct alignment feedback for operators & remove trial & error method

- Laser alignment includes complete shaft system from main gear box to tail rotor gearbox

- Laser can also be potentially used for checking just a portion of the shaft run

- Quick precise alignment checks are easily achieved with the laser system

- Easily record and store data for historical reporting

More Custom Samples

Looking for Something Custom? We’ve Got You Covered.

Contact us at (800) 757-5383 or fill out the form to get started with a custom solution for your business!

[formidable id=56]